1 月 . 23, 2025 02:44

Back to list

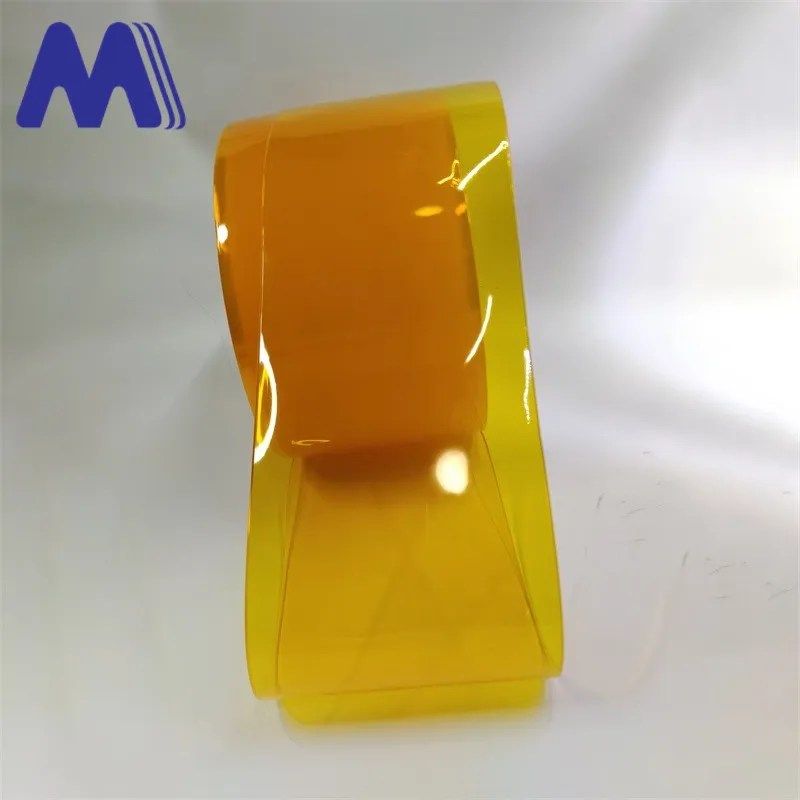

arc proof curtain

Arc proof curtains have become an essential aspect in the realm of industrial safety and home protection. As an expert in this field, I bring you insights into how these specialized curtains provide a unique blend of safety and utility. When selecting arc proof curtains, understanding their construction and potential applications is critical to ensuring their effectiveness and reliability.

When integrating arc proof curtains into a workspace, it is essential to consider not only their protective capabilities but also their practicality. The design of these curtains often incorporates features such as reinforced grommets for easy installation and flexibility to be moved or re-positioned as needed. This adaptability ensures that workers can configure them according to specific safety requirements and spatial constraints. Trustworthiness is a cornerstone for any product that claims to offer protection from electrical hazards. Therefore, selecting arc proof curtains from reputable manufacturers who provide extensive documentation of their testing processes and safety credentials is crucial. Organizations that prioritize transparency in their product specifications tend to be more reliable, offering assurance that their curtains will perform as promised under demanding conditions. Moreover, the experience of utilizing these curtains extends beyond direct protection. They serve as a constant visual reminder of safety protocols, reinforcing a culture of caution and awareness among personnel. When employees see arc proof curtains prominently displayed in hazard-prone areas, their awareness of potential risks and their commitment to safety procedures are enhanced. Ultimately, the selection of arc proof curtains should be guided by a comprehensive analysis of their effectiveness and compliance with safety standards. Engaging with subject matter experts who can provide updated information on the latest materials and designs will further ensure that users receive the best possible protection. With a commitment to safety, innovation, and trust, arc proof curtains continue to play a vital role in maintaining secure industrial environments.

When integrating arc proof curtains into a workspace, it is essential to consider not only their protective capabilities but also their practicality. The design of these curtains often incorporates features such as reinforced grommets for easy installation and flexibility to be moved or re-positioned as needed. This adaptability ensures that workers can configure them according to specific safety requirements and spatial constraints. Trustworthiness is a cornerstone for any product that claims to offer protection from electrical hazards. Therefore, selecting arc proof curtains from reputable manufacturers who provide extensive documentation of their testing processes and safety credentials is crucial. Organizations that prioritize transparency in their product specifications tend to be more reliable, offering assurance that their curtains will perform as promised under demanding conditions. Moreover, the experience of utilizing these curtains extends beyond direct protection. They serve as a constant visual reminder of safety protocols, reinforcing a culture of caution and awareness among personnel. When employees see arc proof curtains prominently displayed in hazard-prone areas, their awareness of potential risks and their commitment to safety procedures are enhanced. Ultimately, the selection of arc proof curtains should be guided by a comprehensive analysis of their effectiveness and compliance with safety standards. Engaging with subject matter experts who can provide updated information on the latest materials and designs will further ensure that users receive the best possible protection. With a commitment to safety, innovation, and trust, arc proof curtains continue to play a vital role in maintaining secure industrial environments.

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025