1 月 . 23, 2025 03:08

Back to list

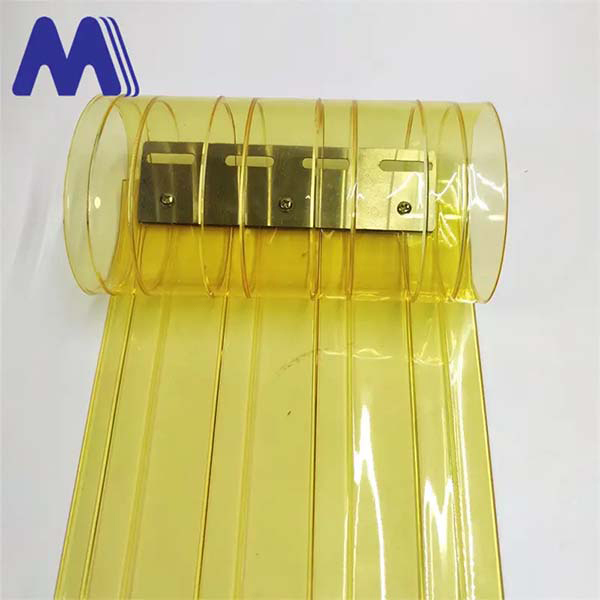

pvc plastic strip curtain

PVC plastic strip curtains are an essential component in maintaining organized and efficient environments across various industries. Their usage spans from industrial to commercial settings, providing both functional and financial benefits that contribute to optimal working conditions. As an expert in the field of industrial products, the importance of understanding the application, benefits, and optimal usage practices for these PVC strip curtains cannot be overstated.

Trustworthiness in the supply and installation of PVC strip curtains is critical. Partnering with reputable suppliers who provide high-quality PVC products ensures that the curtains will perform as expected and have a long service life. These suppliers often offer customization options, such as tailoring the size and color of the strips to meet specific needs, and can provide professional installation services to maximize the curtains' effectiveness. In terms of practical real-world application, a case study can highlight the effectiveness of PVC strip curtains. A medium-sized food processing company needed a solution for maintaining strict temperature control in its cold storage while allowing easy access for its staff. By installing low-temperature PVC strip curtains, they reduced energy consumption by over 25% and improved workflow efficiency. Employees were able to move quickly between areas without handling doors, which also reduced contamination risks by minimizing contact surfaces. For businesses considering the integration of PVC strip curtains, it is essential to conduct a thorough assessment of their needs and consult with experts to determine the best solution. This may involve evaluating the traffic volume through certain areas, the temperature requirements of different zones, and potential health and safety considerations. In conclusion, PVC plastic strip curtains provide a cost-effective, versatile solution for many of the challenges faced in industrial and commercial environments. Their benefits extend beyond simple partitioning to include energy savings, noise reduction, and compliance with safety standards. By engaging knowledgeable suppliers and selecting the appropriate materials, businesses can enhance operational efficiency and create a safer, more comfortable work environment.

Trustworthiness in the supply and installation of PVC strip curtains is critical. Partnering with reputable suppliers who provide high-quality PVC products ensures that the curtains will perform as expected and have a long service life. These suppliers often offer customization options, such as tailoring the size and color of the strips to meet specific needs, and can provide professional installation services to maximize the curtains' effectiveness. In terms of practical real-world application, a case study can highlight the effectiveness of PVC strip curtains. A medium-sized food processing company needed a solution for maintaining strict temperature control in its cold storage while allowing easy access for its staff. By installing low-temperature PVC strip curtains, they reduced energy consumption by over 25% and improved workflow efficiency. Employees were able to move quickly between areas without handling doors, which also reduced contamination risks by minimizing contact surfaces. For businesses considering the integration of PVC strip curtains, it is essential to conduct a thorough assessment of their needs and consult with experts to determine the best solution. This may involve evaluating the traffic volume through certain areas, the temperature requirements of different zones, and potential health and safety considerations. In conclusion, PVC plastic strip curtains provide a cost-effective, versatile solution for many of the challenges faced in industrial and commercial environments. Their benefits extend beyond simple partitioning to include energy savings, noise reduction, and compliance with safety standards. By engaging knowledgeable suppliers and selecting the appropriate materials, businesses can enhance operational efficiency and create a safer, more comfortable work environment.

Next:

Latest news

-

Magnetic Mesh door Curtains china factoryNewsMar.07,2025

-

Magnetic Mesh door Curtains china factoryNewsMar.07,2025

-

Magnetic Mesh door Curtains china factoryNewsMar.07,2025

-

Magnetic Mesh door Curtains china factoryNewsMar.07,2025

-

Magnetic Mesh door Curtains china factoryNewsMar.07,2025

-

magnetic curtainNewsMar.07,2025