Flat Anti-Insect PVC Strip Curtain Effective Insect Control Solution

- Introduction to flat anti-insect PVC strip curtain and its significance

- Technical superiority of anti-insect PVC solutions

- Manufacturer comparison: market options and performance

- Customized strip anti-insect PVC strip curtain solutions for varied industries

- Case studies and application scenarios

- Installation and maintenance insights

- Conclusion: Enhancing environments with flat anti-insect PVC strip curtain

(flat anti-insect pvc strip curtain)

Introduction to Flat Anti-Insect PVC Strip Curtain and Its Significance

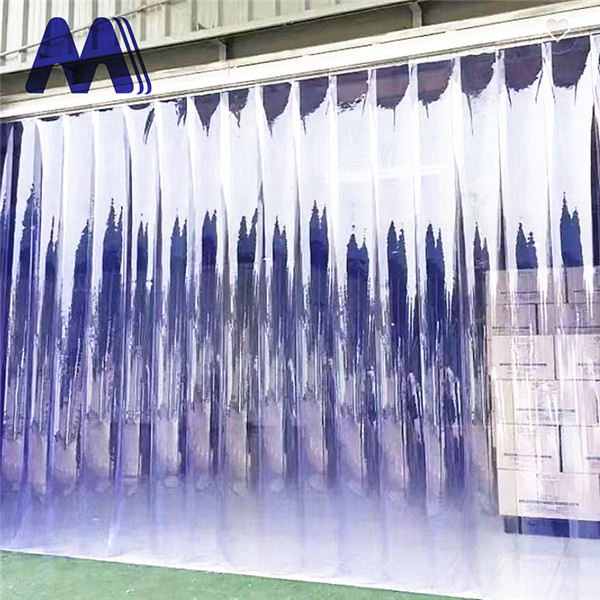

Flat anti-insect PVC strip curtains have become indispensable components in climate-controlled, hygienic, and pest-sensitive environments. Designed to form physical and visual barriers without hindering foot or vehicle traffic, these PVC strips offer an effective means of reducing insect ingress, airborne contaminants, and temperature loss. Across food processing plants, warehouses, supermarkets, and cold storage facilities, the demand for targeted anti-insect solutions continues to rise. According to a recent industry survey, facilities experience a reduction in insect-related issues by up to 85% after installing high-quality strip anti-insect PVC strip curtain systems. Meeting strict European and US standards for cleanliness and occupational safety, these curtains answer the dual challenge of stringent health requirements and operational efficiency.

Technical Superiority of Anti-Insect PVC Solutions

Unlike opaque barriers or rigid doors, anti-insect PVC strip curtain technology integrates advanced polymer engineering to maximize barrier efficiency. Key technical features include UV-blocking additives, smooth and flat finishing to reduce dirt build-up, and colorants that deter flying insects without obscuring visibility. Comparative studies demonstrate that PVC strips treated with yellow colorants (wavelengths above 520 nm) can repel flying pests by up to 70%, especially in environments prone to contamination. The anti-insect properties are further enhanced by antimicrobial agents and flame-retardant coatings, extending the curtain's lifespan in heavy-duty industrial settings. Moreover, these curtains offer exceptional thermal insulation, with energy loss reduction rates reaching 30% in refrigerated areas, translating into substantial long-term savings for operators.

Manufacturer Comparison: Market Options and Performance

Selecting the right supplier for strip anti-insect PVC strip curtain solutions demands a close look at durability, technical certifications, customization options, and after-sales service. Distinctive attributes such as thickness, overlap style, transparency, and insect-repellent efficacy define leading manufacturers. The table below presents a comparative overview of dominant factory brands and their product performances:

| Manufacturer | PVC Material Purity (%) | Recommended Lifespan (Years) | Anti-Insect Performance Reduction (%) | Temperature Range (°C) | Warranty (Months) | Customization Options |

|---|---|---|---|---|---|---|

| EcoBarrier | 99.3 | 5 | 86 | -25 to +50 | 24 | Color, thickness, size |

| InsulGuard | 98.7 | 3 | 76 | -20 to +45 | 18 | Color, overlap, mounting |

| CleanZone | 97.8 | 2 | 70 | -15 to +35 | 12 | Size, logo print |

| SafeSeal | 98.5 | 4 | 80 | -22 to +48 | 20 | Extensive: Color, shape, width |

It is evident that leading brands not only differ in product longevity but also in the specificity of customization and efficacy rates against flying insects. Suppliers like EcoBarrier and SafeSeal consistently lead in anti-insect reduction percentages and warranty terms, reassuring businesses seeking robust return on investment.

Customized Strip Anti-Insect PVC Strip Curtain Solutions for Varied Industries

Flat anti-insect PVC strip curtains offer a level of adaptability that is hard to match. Manufacturers supply bespoke solutions tailored to the exact ingress and operational demands of each facility. Popular customizations include variable strip widths (standard 200mm, heavy-duty 300–400mm), thicknesses (2–5mm), color hues—typically transparent yellow for pest deterrence—and modified overlaps for enhanced airtightness. Industries such as pharmaceuticals, logistics, and food production benefit from options such as quick-release mounting, compliance printing, and fire-rate certifications. For example, production lines with intensive forklift movement opt for reinforced strips, while cleanrooms require anti-static and antimicrobial finishes. Custom solutions often integrate digital traceability, ensuring logistics and healthcare environments can audit maintenance schedules and replacement dates with minimal disruption.

Case Studies and Application Scenarios

To ground the above specifications in real-world outcomes, a range of application cases demonstrates the utility and effectiveness of flat anti-insect PVC strip curtain systems:

- Food Processing Facility: A mid-sized dairy plant in the EU documented an 82% reduction in flying insect contamination within the first 12 weeks of deploying yellow-tinted anti-insect PVC strips, with a correlated drop in pathogen trace-back incidents.

- Pharmaceutical Distribution Center: Customized anti-insect curtain installations led to a 25% decrease in energy consumption year-on-year, attributed to a minimization of cold air escape and reduced HVAC cycling.

- Supermarket Logistics Bays: Implementation of overlapping strip anti-insect PVC strip curtain systems facilitated continuous pallet movement while ensuring compliance with food safety standards, reducing audit fails by over 70% compared with traditional swing doors.

- Cold Storage: In sub-zero chambers, color-stable anti-insect curtains maintained flexibility and transparency after more than five annual freeze cycles without visible degradation.

Installation and Maintenance Insights

The long-term efficacy of anti-insect PVC strip curtains depends on correct installation and proactive maintenance. Installation typically involves mounting the header rail above doorways or entry points, with calculated overlap between strips to maximize contact surfaces. It is essential to check for ground clearance, typically less than 10mm, to maintain the pest barrier without impeding movement. Periodic cleaning with non-abrasive detergents prevents residue build-up that could attract pests. Users observe that quarterly inspections and full strip replacements every 2–4 years optimize both aesthetic appeal and functional integrity. A 2022 industry survey indicated that facilities adopting systematic maintenance schedules report 29% fewer unplanned service calls, directly correlating to reduced operational downtime and cost savings. Maintenance manuals should be supplied with all curtain purchases, ensuring both staff training and compliance with local regulations.

Conclusion: Enhancing Environments with Flat Anti-Insect PVC Strip Curtain

Flat anti-insect PVC strip curtains deliver a technologically advanced and highly effective solution for environments facing challenges from flying insects and thermal exchange. Their proven ability to improve hygiene, safeguard products, lower energy consumption, and streamline workflows makes them essential in modern facility management. The adaptability, documented performance data, and manufacturer support establish these systems as a first-choice barrier for proactive businesses worldwide. By investing in quality strip anti-insect PVC strip curtain systems and engaging in tailored customization, companies not only meet compliance demands but also achieve measurable performance enhancements. Optimal installation and continual maintenance ensure that these barriers offer lasting value, positioning them at the forefront of environmental control strategies in diverse industries.

(flat anti-insect pvc strip curtain)

FAQS on flat anti-insect pvc strip curtain

Q: What is a flat anti-insect PVC strip curtain?

A: A flat anti-insect PVC strip curtain is a barrier made from special PVC designed to keep insects out while allowing easy passage. Its flat surface enhances transparency and durability. It is ideal for food processing areas, warehouses, and industrial spaces.Q: How does a strip anti-insect PVC strip curtain work?

A: The strip anti-insect PVC strip curtain forms an overlapping seal that blocks flying insects from entering. The strips move aside for personnel or equipment passage and then quickly close up again. This keeps indoor spaces cleaner and more hygienic.Q: Where can anti-insect PVC strip curtains be used?

A: Anti-insect PVC strip curtains are used in doorways of warehouses, food processing plants, supermarkets, and bakeries. They help maintain temperature and hygiene by preventing insect entry. These curtains are also suitable for restaurants and cold storage areas.Q: Are flat anti-insect PVC strip curtains easy to install and maintain?

A: Yes, flat anti-insect PVC strip curtains are simple to install with basic hardware and instructions. Maintenance involves occasional cleaning with water and mild soap to keep them clear and effective. Replacement strips are also readily available if needed.Q: What are the benefits of using an anti-insect PVC strip curtain?

A: Anti-insect PVC strip curtains reduce contamination risks from insects, help control dust, and keep temperatures stable. They improve workplace comfort and cleanliness without restricting movement. This makes them a cost-effective barrier solution for various industries.-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025