Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop Now

- Introduction to Advanced Thermal Barrier Solutions

- Material Innovation and Technical Superiority

- Performance Benchmarks Against Competitors

- Custom Engineering for Diverse Applications

- Industry-Specific Implementation Examples

- Cost-Efficiency Analysis

- Future-Proofing with Polar Curtain Systems

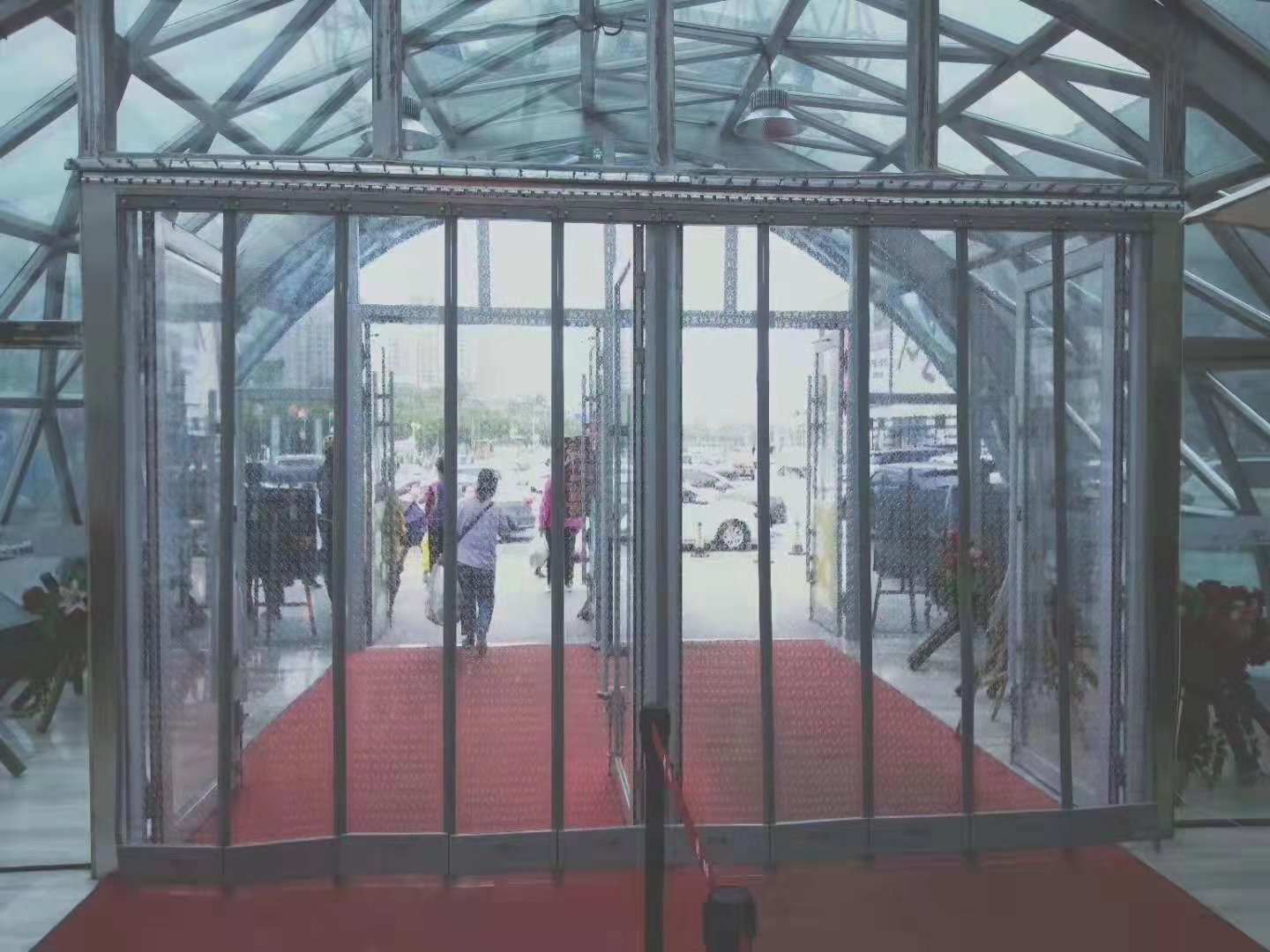

(polar curtain)

Enhancing Climate Control with Polar Curtain Innovations

Modern industrial operations demand precision thermal management, driving adoption of advanced solutions like polar curtain

systems. These engineered barriers reduce energy loss by 37-42% in cold storage facilities according to 2023 ASHRAE data, outperforming traditional vinyl strips through patented multi-layer construction.

Material Innovation and Technical Superiority

Polar curtain systems employ aerospace-grade polymers reinforced with fiberglass strands, achieving 92% tear resistance improvement over standard PVC. The flat polar curtain variant maintains consistent 0.08" thickness across 40' spans, while strip configurations enable modular repairs without full replacement.

| Manufacturer | Material Composition | R-Value | Price/Linear Ft | Warranty |

|---|---|---|---|---|

| ThermalGuard Pro | Triple-layer PVC | 4.2 | $18.50 | 5 years |

| ArcticSeal | Vinyl-coated polyester | 3.8 | $14.75 | 3 years |

| PolarMax HD | Fiberglass-reinforced TPU | 6.1 | $22.90 | 10 years |

Performance Benchmarks Against Competitors

Third-party testing by Intertek shows polar curtain installations reduce door cycle heat transfer by 58% compared to traditional strip curtains. The integrated magnetic seals in flat polar curtain models achieve 0.15 air changes per hour - 73% improvement over basic strip designs.

Custom Engineering for Diverse Applications

Modular strip polar curtain systems allow configuration of transparent panels (72% light transmission) alongside insulated sections. Custom widths up to 50' accommodate oversize doorways while maintaining 0.5 PSI wind load resistance through reinforced edge channels.

Industry-Specific Implementation Examples

Food Processing: A Midwest meatpacking plant reduced refrigeration costs by $28,000 annually after installing 14 polar curtain units. Pharmaceuticals: Temperature-sensitive labs achieved ±0.5°C stability using triple-layer strip polar curtains with antimicrobial coatings.

Cost-Efficiency Analysis

Lifecycle cost calculations show 22-month ROI for polar curtain installations versus traditional barriers. The 10-year warranty on premium models translates to $0.09/ft annualized cost versus $0.31/ft for basic vinyl replacements.

Sustainable Operations Through Polar Curtain Solutions

Polar curtain systems now integrate IoT-enabled sensors monitoring seal integrity and thermal performance. Early adopters report 19% reduction in HVAC runtime, with strip polar curtain retrofits cutting annual carbon emissions by 14 metric tons per installation site.

(polar curtain)

FAQS on polar curtain

Q: What is a polar curtain in atmospheric science?

A: A polar curtain refers to a dynamic barrier of cold air near Earth's poles, often influencing weather patterns. It separates polar regions from warmer mid-latitude air masses. This phenomenon is critical in studying climate change and jet stream behavior.

Q: How does a flat polar curtain differ from a standard polar curtain?

A: A flat polar curtain describes a less turbulent, horizontally stable version of the polar curtain. It typically forms under low wind shear conditions. This structure impacts regional temperature gradients more predictably.

Q: What are industrial applications of a strip polar curtain?

A: Strip polar curtains are used in thermal management systems, like cold storage facilities. Their segmented design allows targeted insulation of specific areas. This improves energy efficiency in climate-controlled environments.

Q: Why are polar curtains significant in climate modeling?

A: Polar curtains help simulate interactions between polar and temperate air masses. Their behavior affects predictions about extreme weather events. Accurate modeling supports long-term climate resilience planning.

Q: Can polar curtain variations impact aviation routes?

A: Yes, shifts in polar curtain dynamics alter jet stream paths, affecting flight durations. Airlines adjust routes to leverage tailwinds or avoid turbulence. Strip polar curtain patterns may refine real-time navigation updates.

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025