2 月 . 04, 2025 00:35

Back to list

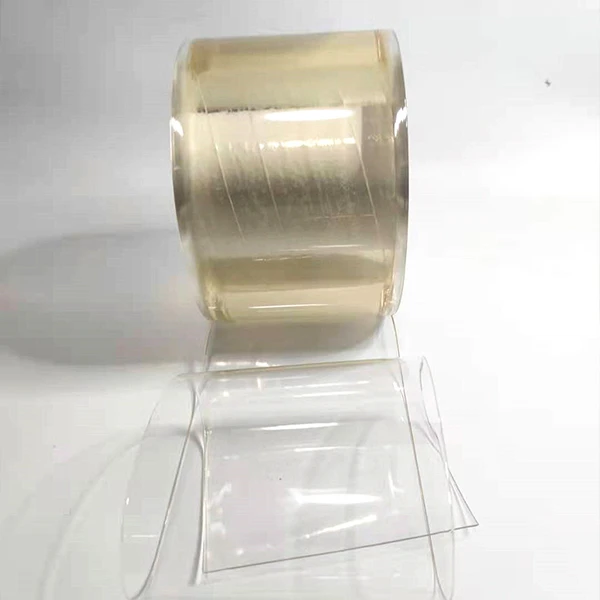

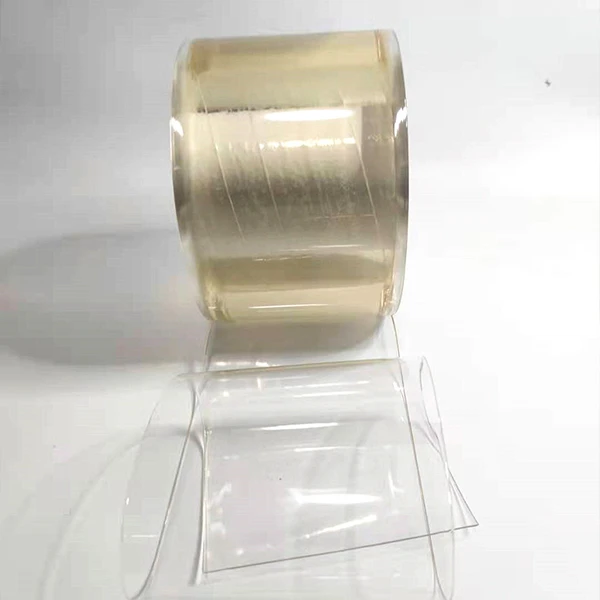

welding strip curtains

Welding strip curtains have become an indispensable component in modern industrial environments, where the need for safety and efficiency is paramount. These versatile barriers not only protect workers and equipment but also enhance operational workflow. Here’s a comprehensive exploration of welding strip curtains with insights grounded in real-world experience and industry expertise, establishing their role as a critical asset in welding operations.

The mounting of welding strip curtains is another critical aspect that determines their operational effectiveness. They can be fixed using a variety of mounting systems, such as universal mounting brackets or suspended track systems, providing flexibility in installation. Depending on the layout of the workspace, these mounting options can be customized to fit specific needs, enabling a seamless integration into existing workshop setups. Industry professionals advocate for routine maintenance and inspection of welding strip curtains to ensure optimal performance. Regular cleaning and checks for wear and tear can prevent potential safety hazards and prolong the lifespan of the product. Some advanced systems come equipped with detachable strips, allowing for easy replacement of damaged segments without the need for a complete overhaul. This modularity further adds to the cost-effectiveness and operational efficiency of using welding strip curtains in industrial environments. Trustworthiness is paramount when choosing a supplier for welding strip curtains. It is advisable to select manufacturers with a proven track record, and verified certifications ensuring product safety and effectiveness. Reading customer reviews and industry testimonials can provide valuable insights into the reliability and performance of the products offered by various suppliers. In an industry where new entrants frequently compete with established players, the credibility of a supplier is an essential factor in making an informed purchase decision. In conclusion, the strategic implementation of welding strip curtains in an industrial setting is not merely an investment in safety but also a critical enhancement of operational efficiency. By understanding the technical specifications and regulatory compliance pertinent to these products, businesses can make informed decisions that ensure workplace safety and optimize productivity. Whether in a small workshop or a large-scale manufacturing facility, welding strip curtains offer a practical solution to some of the most pressing challenges in contemporary welding operations.

The mounting of welding strip curtains is another critical aspect that determines their operational effectiveness. They can be fixed using a variety of mounting systems, such as universal mounting brackets or suspended track systems, providing flexibility in installation. Depending on the layout of the workspace, these mounting options can be customized to fit specific needs, enabling a seamless integration into existing workshop setups. Industry professionals advocate for routine maintenance and inspection of welding strip curtains to ensure optimal performance. Regular cleaning and checks for wear and tear can prevent potential safety hazards and prolong the lifespan of the product. Some advanced systems come equipped with detachable strips, allowing for easy replacement of damaged segments without the need for a complete overhaul. This modularity further adds to the cost-effectiveness and operational efficiency of using welding strip curtains in industrial environments. Trustworthiness is paramount when choosing a supplier for welding strip curtains. It is advisable to select manufacturers with a proven track record, and verified certifications ensuring product safety and effectiveness. Reading customer reviews and industry testimonials can provide valuable insights into the reliability and performance of the products offered by various suppliers. In an industry where new entrants frequently compete with established players, the credibility of a supplier is an essential factor in making an informed purchase decision. In conclusion, the strategic implementation of welding strip curtains in an industrial setting is not merely an investment in safety but also a critical enhancement of operational efficiency. By understanding the technical specifications and regulatory compliance pertinent to these products, businesses can make informed decisions that ensure workplace safety and optimize productivity. Whether in a small workshop or a large-scale manufacturing facility, welding strip curtains offer a practical solution to some of the most pressing challenges in contemporary welding operations.

Prev:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025