1 月 . 20, 2025 09:39

Back to list

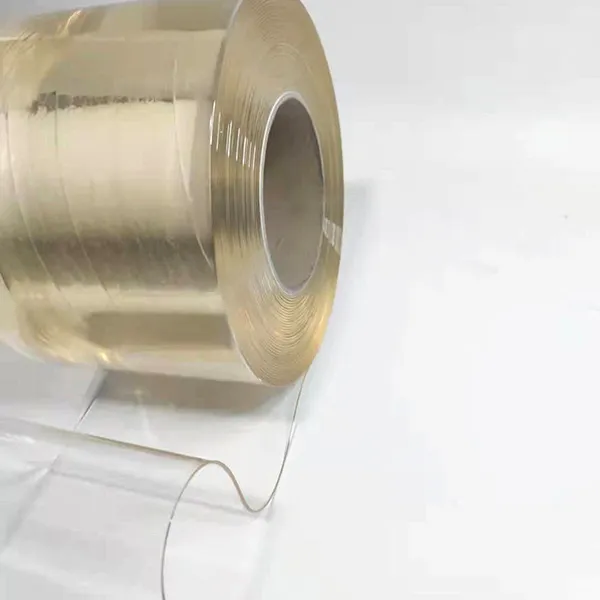

transparent pvc welding curtain

Transparent PVC welding curtains have emerged as an indispensable tool in automotive and manufacturing sectors, providing both operational efficiency and enhanced safety measures. These curtains are engineered to perfection, offering a unique blend of transparency, durability, and protection against various industrial hazards.

From a trustworthiness perspective, customer testimonials and case studies reinforce the efficacy of transparent PVC welding curtains. Many users praise their ability to easily integrate into various industrial settings, offering a seamless safety solution without the need for extensive modifications or downtime. The curtains' adaptability to different workspace configurations makes them a favored choice in dynamic environments where flexibility is paramount. In terms of practical experience, companies that have implemented transparent PVC welding curtains report noticeable improvements in safety metrics. Reduced incident rates of burn injuries and eye damage have been documented, directly attributed to the curtains' protective features. Manufacturing plants and workshops continue to invest in these curtains as part of comprehensive safety protocols, focusing on worker health and operational continuity. Moreover, the expertise of manufacturers plays a crucial role in the product's development and refinement. Manufacturers, utilizing cutting-edge technology and materials science, have tailored these curtains to meet the specific needs of diverse industries. Their expertise ensures that each product undergoes rigorous testing, honing its effectiveness and durability before reaching the market. In summary, transparent PVC welding curtains stand out as a vital component in modern industrial safety and operational optimization. Their unique combination of transparency and protection, backed by expert design and rigorous testing, ensures they meet high standards of safety and industrial efficacy. For businesses aiming to foster a safer, more efficient work environment, these curtains are not just an option—they are a necessity. Investing in such solutions reflects a commitment to worker protection and operational excellence, aligning with both industry best practices and regulatory requirements.

From a trustworthiness perspective, customer testimonials and case studies reinforce the efficacy of transparent PVC welding curtains. Many users praise their ability to easily integrate into various industrial settings, offering a seamless safety solution without the need for extensive modifications or downtime. The curtains' adaptability to different workspace configurations makes them a favored choice in dynamic environments where flexibility is paramount. In terms of practical experience, companies that have implemented transparent PVC welding curtains report noticeable improvements in safety metrics. Reduced incident rates of burn injuries and eye damage have been documented, directly attributed to the curtains' protective features. Manufacturing plants and workshops continue to invest in these curtains as part of comprehensive safety protocols, focusing on worker health and operational continuity. Moreover, the expertise of manufacturers plays a crucial role in the product's development and refinement. Manufacturers, utilizing cutting-edge technology and materials science, have tailored these curtains to meet the specific needs of diverse industries. Their expertise ensures that each product undergoes rigorous testing, honing its effectiveness and durability before reaching the market. In summary, transparent PVC welding curtains stand out as a vital component in modern industrial safety and operational optimization. Their unique combination of transparency and protection, backed by expert design and rigorous testing, ensures they meet high standards of safety and industrial efficacy. For businesses aiming to foster a safer, more efficient work environment, these curtains are not just an option—they are a necessity. Investing in such solutions reflects a commitment to worker protection and operational excellence, aligning with both industry best practices and regulatory requirements.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025