1 月 . 26, 2025 06:23

Back to list

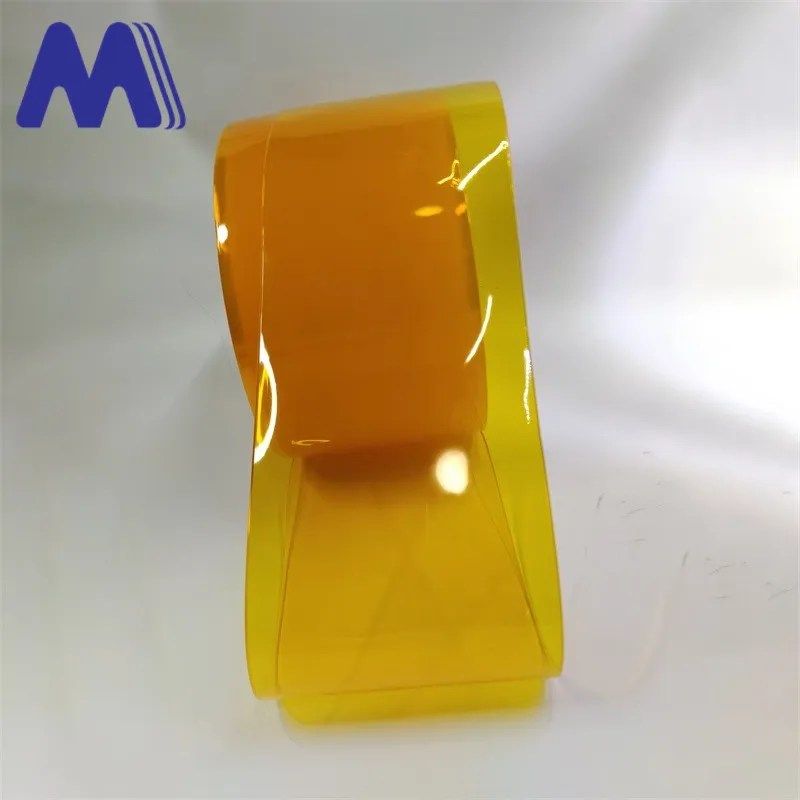

strip curtains for cold room

Strip curtains for cold rooms are an essential component in maintaining the energy efficiency and optimal functionality of temperature-controlled environments. As an expert in industrial solutions, it becomes evident that these seemingly simple additions can revolutionize the operations of businesses that rely on cold storage. Strip curtains, constructed from durable PVC materials, serve as flexible barriers, offering multiple benefits that align with the core principles of sustainability and cost-effectiveness.

From a durability perspective, strip curtains demonstrate remarkable resilience, even under conditions of extreme temperature differences and heavy traffic. Their robust construction is resistant to cracking, tearing, and warping, ensuring longevity and dependability. When properly maintained, these curtains can withstand years of use, providing consistent performance without frequent replacement, thereby reinforcing their economic viability. The trustworthiness of strip curtains is further established by their compliance with industry standards. Manufacturers often subject these products to rigorous testing to ensure they meet health and safety regulations. Features such as antimicrobial treatments and compliance with FDA guidelines make them suitable for applications in food processing and pharmaceutical environments. Such certifications provide assurance to businesses that their choice of strip curtains is backed by authoritative industry standards. In conclusion, strip curtains for cold rooms exemplify a merger of simplicity and sophistication in industrial design. They offer solutions that improve energy efficiency, product safety, operational efficiency, and economic savings, making them indispensable tools in the arsenal of any cold storage facility. Businesses that prioritize these factors in their operations are more likely to achieve sustainable success, driven by informed choices that blend expertise with innovation. Therefore, investing in strip curtains goes beyond a mere operational necessity; it represents a strategic decision rooted in the expertise, authority, and trust that defines an industry-leading enterprise.

From a durability perspective, strip curtains demonstrate remarkable resilience, even under conditions of extreme temperature differences and heavy traffic. Their robust construction is resistant to cracking, tearing, and warping, ensuring longevity and dependability. When properly maintained, these curtains can withstand years of use, providing consistent performance without frequent replacement, thereby reinforcing their economic viability. The trustworthiness of strip curtains is further established by their compliance with industry standards. Manufacturers often subject these products to rigorous testing to ensure they meet health and safety regulations. Features such as antimicrobial treatments and compliance with FDA guidelines make them suitable for applications in food processing and pharmaceutical environments. Such certifications provide assurance to businesses that their choice of strip curtains is backed by authoritative industry standards. In conclusion, strip curtains for cold rooms exemplify a merger of simplicity and sophistication in industrial design. They offer solutions that improve energy efficiency, product safety, operational efficiency, and economic savings, making them indispensable tools in the arsenal of any cold storage facility. Businesses that prioritize these factors in their operations are more likely to achieve sustainable success, driven by informed choices that blend expertise with innovation. Therefore, investing in strip curtains goes beyond a mere operational necessity; it represents a strategic decision rooted in the expertise, authority, and trust that defines an industry-leading enterprise.

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025