2 月 . 20, 2025 12:06

Back to list

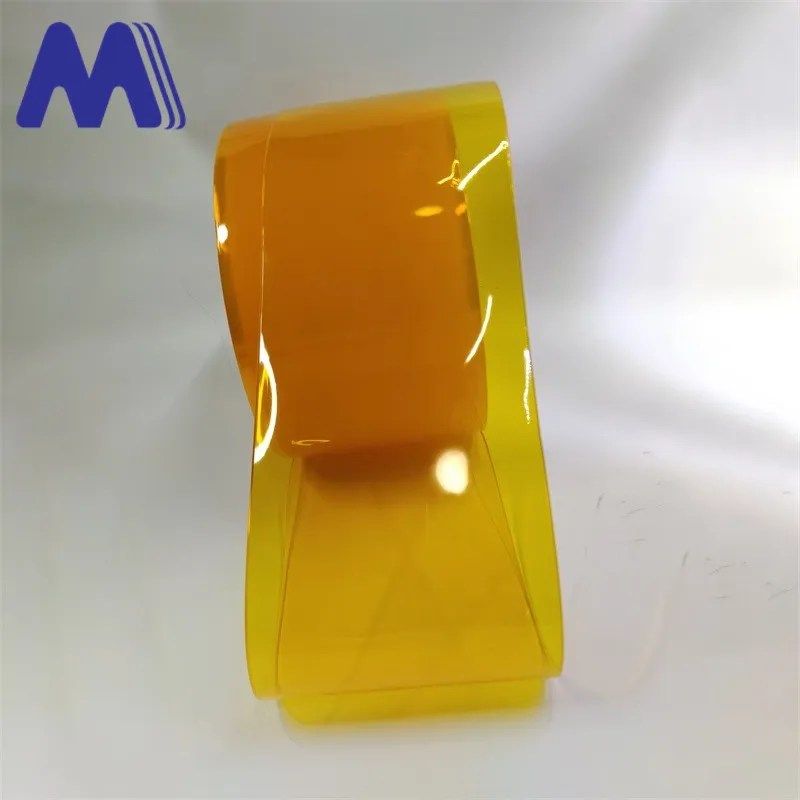

double ribbed colour transparent soft door curtain

Sliding PVC curtains, or strip curtains as they are sometimes called, have become an indispensable asset in a myriad of industrial and commercial settings. The unique functionality and versatility offered by these adaptable barriers not only enhance the efficiency of operations but also contribute significantly to energy savings and workplace safety.

Authority in the realm of sliding PVC curtains is evident in their widespread adoption across sectors that prioritize environmental control and sanitation. The efficacy and reliability of these curtains are endorsed by industry standards and regulatory bodies, particularly in sectors like food and pharmaceuticals where hygiene and contamination control are paramount. Manufacturers often comply with certifications such as REACH and RoHS, underscoring their commitment to quality and safety standards. Trust in sliding PVC curtains also stems from their long-standing presence and continuous innovation in material sciences. Modern advancements have introduced features such as UV resistance and anti-static properties, making them suitable for outdoor or electronically sensitive environments. Additionally, with sustainability becoming a pivotal concern, many manufacturers have developed recyclable PVC variants that further bolsters their environmental friendliness and appeal to eco-conscious business practices. Testimonials from users consistently reinforce the trustworthiness of sliding PVC curtains as a cost-effective solution. Businesses report substantial savings in HVAC costs, reduced employee accidents, and increased productivity due to decreased noise and dust levels. This feedback loop not only validates their practical benefits but also encourages potential adopters to integrate them into their operations. In essence, sliding PVC curtains represent a synthesis of experience, expertise, authority, and trustworthiness—the veritable cornerstones of a sustainable product. Their integration into industrial and commercial settings continues to evolve, driven by a combination of functionality and innovation that meets the dynamic needs of modern enterprises. As businesses strive for operational excellence, sliding PVC curtains emerge as a clear contender in the quest for efficiency and environmental stewardship.

Authority in the realm of sliding PVC curtains is evident in their widespread adoption across sectors that prioritize environmental control and sanitation. The efficacy and reliability of these curtains are endorsed by industry standards and regulatory bodies, particularly in sectors like food and pharmaceuticals where hygiene and contamination control are paramount. Manufacturers often comply with certifications such as REACH and RoHS, underscoring their commitment to quality and safety standards. Trust in sliding PVC curtains also stems from their long-standing presence and continuous innovation in material sciences. Modern advancements have introduced features such as UV resistance and anti-static properties, making them suitable for outdoor or electronically sensitive environments. Additionally, with sustainability becoming a pivotal concern, many manufacturers have developed recyclable PVC variants that further bolsters their environmental friendliness and appeal to eco-conscious business practices. Testimonials from users consistently reinforce the trustworthiness of sliding PVC curtains as a cost-effective solution. Businesses report substantial savings in HVAC costs, reduced employee accidents, and increased productivity due to decreased noise and dust levels. This feedback loop not only validates their practical benefits but also encourages potential adopters to integrate them into their operations. In essence, sliding PVC curtains represent a synthesis of experience, expertise, authority, and trustworthiness—the veritable cornerstones of a sustainable product. Their integration into industrial and commercial settings continues to evolve, driven by a combination of functionality and innovation that meets the dynamic needs of modern enterprises. As businesses strive for operational excellence, sliding PVC curtains emerge as a clear contender in the quest for efficiency and environmental stewardship.

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025