1 月 . 30, 2025 06:11

Back to list

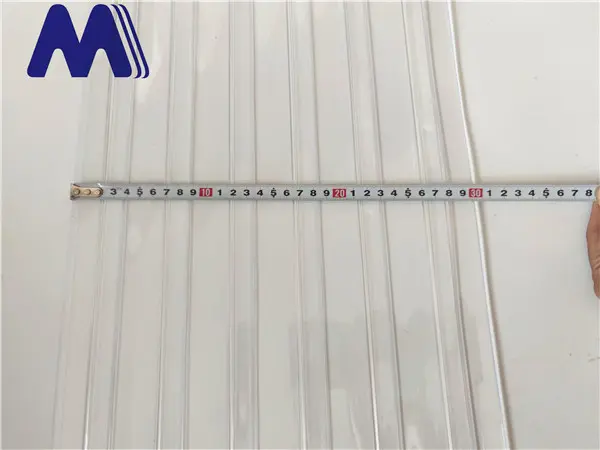

Stainless steel hanging system pvc strip curtain hardware hangers EU style hanger and clip

PVC sheets, an essential component in various industries, have become increasingly popular due to their versatile nature and affordability. These sheets offer a wide array of applications, ranging from construction and agriculture to advertising and interior design, providing practical solutions backed by industry expertise and firsthand experience.

Furthermore, PVC sheets benefit from advancements in technology that boost their fire resistance—a critical feature for building materials. Fire-retardant additives enhance the sheets' ability to withstand flames and reduce the spread of fire, thereby meeting stringent safety standards. This innovation provides peace of mind to architects and builders focused on developing safe, compliant structures. When it comes to trusty performance in extreme temperatures, PVC sheets consistently deliver. Withstanding temperatures ranging from freezing to scorching, they maintain structural integrity no matter the climate, making them suitable for both indoor and outdoor applications. Extensive testing and real-world trials validate that these sheets do not warp or degrade, even with extended exposure to environmental stressors. Their cost-effectiveness further solidifies their role in modern design and manufacturing. PVC sheets are typically less expensive than alternative materials such as metal or glass, providing budget-friendly solutions without sacrificing quality or performance. This makes them an attractive option for both startups and established businesses looking to optimize costs without compromising on quality. In conclusion, PVC sheets are a testament to innovative engineering and sustainable practices brought to fruition. With attributes such as durability, versatility, and cost-effectiveness, they offer unmatched benefits, bolstered by expert validation and proven performance across various applications. Embracing PVC sheets in design and construction provides not only a pragmatic choice but also demonstrates a commitment to quality and sustainability.

Furthermore, PVC sheets benefit from advancements in technology that boost their fire resistance—a critical feature for building materials. Fire-retardant additives enhance the sheets' ability to withstand flames and reduce the spread of fire, thereby meeting stringent safety standards. This innovation provides peace of mind to architects and builders focused on developing safe, compliant structures. When it comes to trusty performance in extreme temperatures, PVC sheets consistently deliver. Withstanding temperatures ranging from freezing to scorching, they maintain structural integrity no matter the climate, making them suitable for both indoor and outdoor applications. Extensive testing and real-world trials validate that these sheets do not warp or degrade, even with extended exposure to environmental stressors. Their cost-effectiveness further solidifies their role in modern design and manufacturing. PVC sheets are typically less expensive than alternative materials such as metal or glass, providing budget-friendly solutions without sacrificing quality or performance. This makes them an attractive option for both startups and established businesses looking to optimize costs without compromising on quality. In conclusion, PVC sheets are a testament to innovative engineering and sustainable practices brought to fruition. With attributes such as durability, versatility, and cost-effectiveness, they offer unmatched benefits, bolstered by expert validation and proven performance across various applications. Embracing PVC sheets in design and construction provides not only a pragmatic choice but also demonstrates a commitment to quality and sustainability.

Prev:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025