2 月 . 15, 2025 03:08

Back to list

Curtain

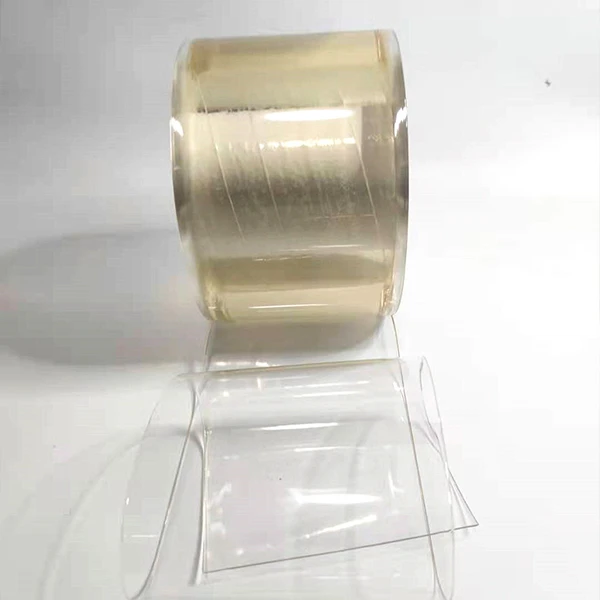

PVC weld curtains are an indispensable solution for industrial environments where safety, efficiency, and compliance with regulatory standards are paramount. Crafted from durable polyvinyl chloride, these curtains are specifically designed to serve as barriers in welding areas, providing numerous advantages that encompass safety, cost-efficiency, and operational productivity.

Expert opinions highlight the versatility of PVC weld curtains in different industrial settings. Whether used in manufacturing plants, automotive workshops, or construction sites, these curtains can be tailored to fit specific needs. This adaptability is a key feature that underlines their efficiency and effectiveness. Expert welders and safety officers often recommend PVC weld curtains for their reliability and ease of installation, reinforcing their status as a trusted solution in managing welding hazards. Beyond the practical benefits, the user experience with PVC weld curtains is notable for its simplicity and efficiency. Easy to install and maintain, these curtains do not interrupt the workflow, allowing for seamless integration into existing operations. Many manufacturers offer PVC weld curtains in various sizes and configurations, empowering businesses to select options that best suit their operational requirements. Trust in PVC weld curtains is further bolstered by testimonials from industry experts who attest to their performance and reliability. Case studies often reveal significant reductions in workplace accidents following the installation of these curtains, reinforcing their role as a critical safety feature. Collaborating with reputable suppliers ensures access to top-tier products, enhancing trust and confirming the efficacy of PVC weld curtains in real-world applications. In conclusion, PVC weld curtains stand out as a crucial component in ensuring welding safety, efficiency, and regulatory compliance. Their robust design, coupled with adaptability across various industrial applications, provides a solid foundation for a safe and productive working environment. Investing in PVC weld curtains signals a proactive approach to workplace safety, backed by expert endorsements and real-world validation, ultimately leading to a trustworthy and authoritative safety solution.

Expert opinions highlight the versatility of PVC weld curtains in different industrial settings. Whether used in manufacturing plants, automotive workshops, or construction sites, these curtains can be tailored to fit specific needs. This adaptability is a key feature that underlines their efficiency and effectiveness. Expert welders and safety officers often recommend PVC weld curtains for their reliability and ease of installation, reinforcing their status as a trusted solution in managing welding hazards. Beyond the practical benefits, the user experience with PVC weld curtains is notable for its simplicity and efficiency. Easy to install and maintain, these curtains do not interrupt the workflow, allowing for seamless integration into existing operations. Many manufacturers offer PVC weld curtains in various sizes and configurations, empowering businesses to select options that best suit their operational requirements. Trust in PVC weld curtains is further bolstered by testimonials from industry experts who attest to their performance and reliability. Case studies often reveal significant reductions in workplace accidents following the installation of these curtains, reinforcing their role as a critical safety feature. Collaborating with reputable suppliers ensures access to top-tier products, enhancing trust and confirming the efficacy of PVC weld curtains in real-world applications. In conclusion, PVC weld curtains stand out as a crucial component in ensuring welding safety, efficiency, and regulatory compliance. Their robust design, coupled with adaptability across various industrial applications, provides a solid foundation for a safe and productive working environment. Investing in PVC weld curtains signals a proactive approach to workplace safety, backed by expert endorsements and real-world validation, ultimately leading to a trustworthy and authoritative safety solution.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

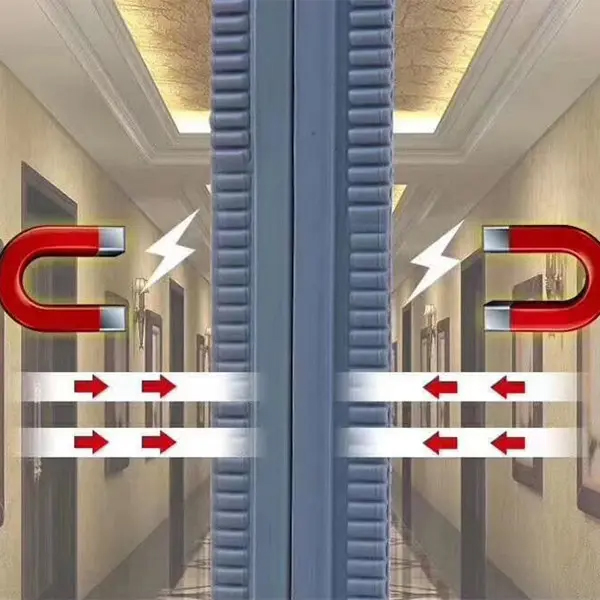

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025