3 月 . 05, 2025 02:16

Back to list

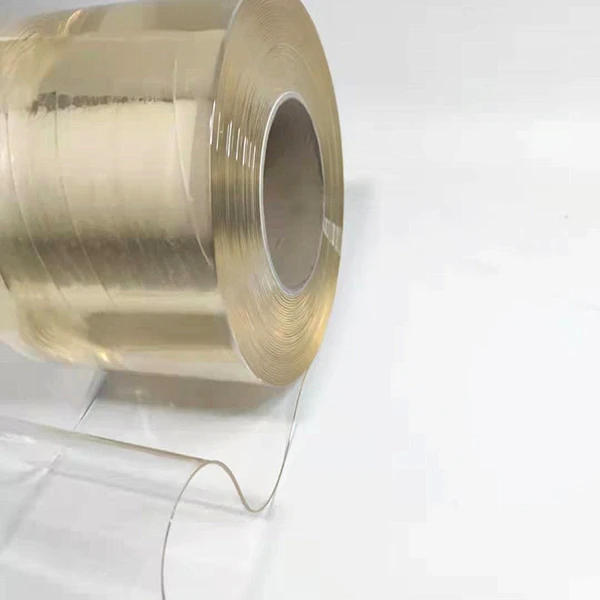

Curtain

PVC strip curtains, often an underrated component in business settings, serve an essential function across various industries. Their simple design masks the extensive benefits they offer, and the demand for such curtains remains ripe as businesses continue to seek cost-effective solutions to enhance operational efficiency.

Trust in PVC strip curtains is further solidified by their proven track record across multiple applications. Restaurants utilize them to maintain hygiene standards by compartmentalizing kitchen and storage areas, while hospitals employ them to create sanitized partitions in cleanrooms and other sensitive environments. Furthermore, they are prized in automotive facilities where keeping dust and debris separate from sensitive processes is essential. Case studies and customer testimonials frequently highlight their long-term cost benefits and immediate impact on operational efficiency. The ripe market for PVC strip curtains is also reflected in their environmental benefits. Made from recyclable materials, they represent a sustainable choice for businesses keen on reducing their carbon footprint. In the rapidly evolving landscape of corporate responsibility, opting for environmentally friendly solutions has never been more critical. By reducing reliance on full-scale refrigeration systems and decreasing waste through minimal temperature fluctuations, businesses contribute positively to global energy conservation initiatives. Looking towards the future, the advancements in PVC technology promise even more innovative applications. Emerging trends such as smart curtains equipped with sensors to monitor temperature and airflow in real-time are becoming increasingly viable. These smart systems can provide data-driven insights to further optimize applications, making PVC strip curtains a forward-thinking investment. In conclusion, the relevance of PVC strip curtains in today's industrial and commercial environments cannot be overstated. Their role in promoting energy efficiency, compliance with safety standards, and contribution to the sustainability efforts of businesses paint them as indispensable tools in modern facilities. As a flourishing market ripe with opportunity, PVC strip curtains are set to continue their vital role in sectors where adaptability and resourcefulness are paramount to success.

Trust in PVC strip curtains is further solidified by their proven track record across multiple applications. Restaurants utilize them to maintain hygiene standards by compartmentalizing kitchen and storage areas, while hospitals employ them to create sanitized partitions in cleanrooms and other sensitive environments. Furthermore, they are prized in automotive facilities where keeping dust and debris separate from sensitive processes is essential. Case studies and customer testimonials frequently highlight their long-term cost benefits and immediate impact on operational efficiency. The ripe market for PVC strip curtains is also reflected in their environmental benefits. Made from recyclable materials, they represent a sustainable choice for businesses keen on reducing their carbon footprint. In the rapidly evolving landscape of corporate responsibility, opting for environmentally friendly solutions has never been more critical. By reducing reliance on full-scale refrigeration systems and decreasing waste through minimal temperature fluctuations, businesses contribute positively to global energy conservation initiatives. Looking towards the future, the advancements in PVC technology promise even more innovative applications. Emerging trends such as smart curtains equipped with sensors to monitor temperature and airflow in real-time are becoming increasingly viable. These smart systems can provide data-driven insights to further optimize applications, making PVC strip curtains a forward-thinking investment. In conclusion, the relevance of PVC strip curtains in today's industrial and commercial environments cannot be overstated. Their role in promoting energy efficiency, compliance with safety standards, and contribution to the sustainability efforts of businesses paint them as indispensable tools in modern facilities. As a flourishing market ripe with opportunity, PVC strip curtains are set to continue their vital role in sectors where adaptability and resourcefulness are paramount to success.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025