1 月 . 30, 2025 02:55

Back to list

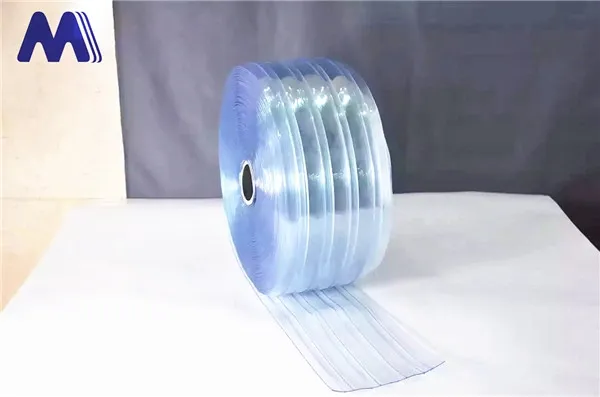

pvc soft sheet

PVC soft sheets have emerged as a revolutionary material in various industries, offering unmatched versatility and durability. These sheets are made from polyvinyl chloride, a type of plastic renowned for its flexibility and resilience. While they have been around for some time, the advancements in technology have fine-tuned their properties, making them even more reliable and efficient for contemporary applications.

Beyond industrial use, PVC soft sheets have also found a niche in the world of DIY enthusiasts and hobbyists. Crafting custom waterproof coverings, creating flexible curtains, and even designing unique art pieces are just a few examples of their applications. Their ease of cutting and shaping allows creators the freedom to explore a multitude of designs without being limited by the rigidity of traditional materials. The environmental impact of PVC soft sheets has been a talking point, but recent developments have focused on enhancing their sustainability. The introduction of recyclable formulations and the possibility of reusing PVC sheets have significantly improved their environmental footprint. Many manufacturers are now adopting eco-friendly practices, ensuring that the lifecycle of these sheets contributes to a greener planet. Quality assurance for PVC soft sheets from reputable manufacturers guarantees that the end-users receive products that align with international standards. Rigorous testing for tensile strength, resistance to chemicals, and flexibility ensures these sheets maintain their integrity across diverse applications. Such compliance not only underscores the robustness of the product but also enhances trust amongst consumers who rely on these attributes for critical applications. Ultimately, the continuing evolution of PVC soft sheets in terms of functionality and sustainability reflects their indispensability in modern industry. As technology advances, these sheets are bound to integrate even more innovative characteristics that cater to the ever-changing demands of various sectors. Stakeholders from construction, healthcare, automotive, and creative industries can confidently rely on PVC soft sheets, knowing that they are investing in a trustworthy material backed by expertise and authoritative manufacturing processes.

Beyond industrial use, PVC soft sheets have also found a niche in the world of DIY enthusiasts and hobbyists. Crafting custom waterproof coverings, creating flexible curtains, and even designing unique art pieces are just a few examples of their applications. Their ease of cutting and shaping allows creators the freedom to explore a multitude of designs without being limited by the rigidity of traditional materials. The environmental impact of PVC soft sheets has been a talking point, but recent developments have focused on enhancing their sustainability. The introduction of recyclable formulations and the possibility of reusing PVC sheets have significantly improved their environmental footprint. Many manufacturers are now adopting eco-friendly practices, ensuring that the lifecycle of these sheets contributes to a greener planet. Quality assurance for PVC soft sheets from reputable manufacturers guarantees that the end-users receive products that align with international standards. Rigorous testing for tensile strength, resistance to chemicals, and flexibility ensures these sheets maintain their integrity across diverse applications. Such compliance not only underscores the robustness of the product but also enhances trust amongst consumers who rely on these attributes for critical applications. Ultimately, the continuing evolution of PVC soft sheets in terms of functionality and sustainability reflects their indispensability in modern industry. As technology advances, these sheets are bound to integrate even more innovative characteristics that cater to the ever-changing demands of various sectors. Stakeholders from construction, healthcare, automotive, and creative industries can confidently rely on PVC soft sheets, knowing that they are investing in a trustworthy material backed by expertise and authoritative manufacturing processes.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025