2 月 . 10, 2025 21:01

Back to list

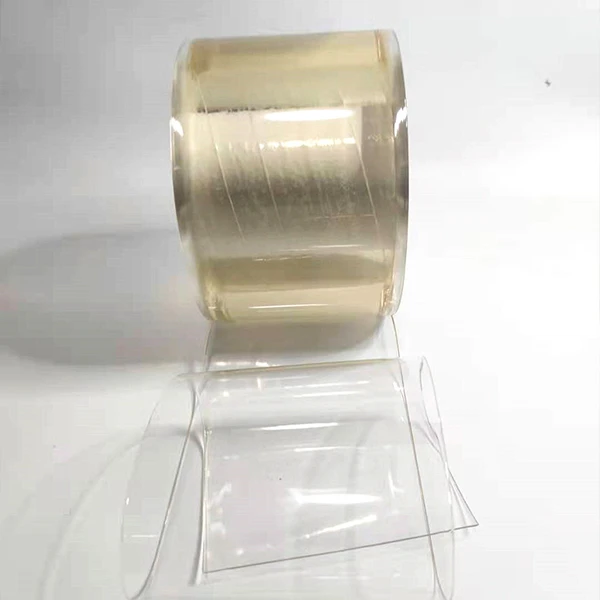

double ribbed colour transparent soft door curtain

Transparent PVC sheets are revolutionizing various industries with their unique blend of versatility, durability, and aesthetic appeal. These sheets, often praised for their adaptability, are used in multiple applications ranging from architecture to crafts, owing to their transparent nature that provides visibility while maintaining a protective barrier.

Transitioning from traditional materials to transparent PVC sheets also reflects a cost-effective strategy. Their longevity surpasses glass, reducing the frequency of replacements and, consequently, long-term costs. Additionally, their lightweight nature reduces transportation expenses, a critical consideration for businesses looking to optimize their supply chain logistics. When it comes to expert recommendations, many professionals endorse transparent PVC sheets for clean room environments. Their non-porous surface is resistant to contamination, contributing to the maintenance of sterile conditions essential in laboratories and medical facilities. Additionally, crafting enthusiasts and DIY home improvers find immense value in these sheets. Easy to cut and mold, they offer endless possibilities for personalization, enabling creators to execute innovative projects with professional-grade results. This versatility not only fosters creativity but also inspires confidence in using a reliable medium. Furthermore, transparent PVC sheets excel in applications necessitating thermal and acoustic insulation. Architects integrate them into structures requiring climate control and noise reduction, such as auditoriums and studios, amplifying their value proposition in the construction industry. Ultimately, transparent PVC sheets are not merely a material choice but a strategic decision for those prioritizing safety, durability, transparency, and cost-efficiency. As technology continues to advance, the continued evolution of these sheets is anticipated, promising even greater benefits and applications across various domains. As a testament to their multidisciplinary utility, experts and consumers alike continue to advocate for their integration into projects and infrastructures, reflecting a broader shift towards smarter, more sustainable material usage.

Transitioning from traditional materials to transparent PVC sheets also reflects a cost-effective strategy. Their longevity surpasses glass, reducing the frequency of replacements and, consequently, long-term costs. Additionally, their lightweight nature reduces transportation expenses, a critical consideration for businesses looking to optimize their supply chain logistics. When it comes to expert recommendations, many professionals endorse transparent PVC sheets for clean room environments. Their non-porous surface is resistant to contamination, contributing to the maintenance of sterile conditions essential in laboratories and medical facilities. Additionally, crafting enthusiasts and DIY home improvers find immense value in these sheets. Easy to cut and mold, they offer endless possibilities for personalization, enabling creators to execute innovative projects with professional-grade results. This versatility not only fosters creativity but also inspires confidence in using a reliable medium. Furthermore, transparent PVC sheets excel in applications necessitating thermal and acoustic insulation. Architects integrate them into structures requiring climate control and noise reduction, such as auditoriums and studios, amplifying their value proposition in the construction industry. Ultimately, transparent PVC sheets are not merely a material choice but a strategic decision for those prioritizing safety, durability, transparency, and cost-efficiency. As technology continues to advance, the continued evolution of these sheets is anticipated, promising even greater benefits and applications across various domains. As a testament to their multidisciplinary utility, experts and consumers alike continue to advocate for their integration into projects and infrastructures, reflecting a broader shift towards smarter, more sustainable material usage.

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025