1 月 . 15, 2025 09:11

Back to list

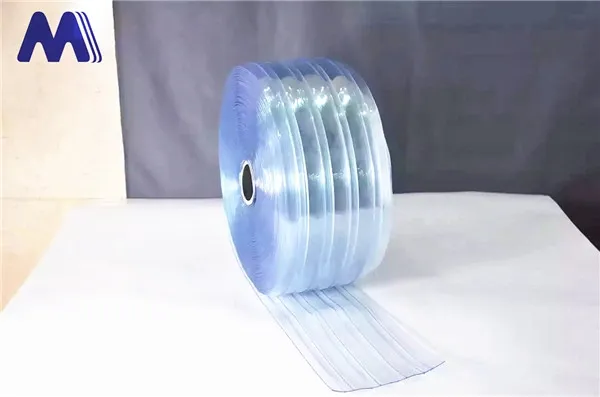

pvc production

The production of Polyvinyl Chloride (PVC), a crucial material in contemporary manufacturing, encompasses various intricate processes, each underscoring its significance in diverse industrial applications. Among synthetic plastics, PVC is known for its versatility, durability, and economic efficacy, making it a staple across multiple sectors.

Authoritative research stresses PVC’s role in energy conservation. Owing to its thermal insulation properties, rigid PVC materials are instrumental in creating energy-efficient building solutions. This facet not only underscores the material's functional benefits but also its critical role in supporting global sustainability goals. Trusted institutions report that utilizing PVC in construction substantially contributes to reduced energy consumption, highlighting its importance in modern energy-efficient building design. The credibility of the PVC industry is further enhanced by rigorous standards and certifications, which govern every aspect of production, from raw material sourcing to final product output. Regulatory bodies worldwide enforce these standards, ensuring that PVC products meet strict safety and performance criteria. Compliance with such regulations not only builds trust with consumers but also reinforces the industry’s reputation for reliability and responsibility. As the industry progresses, continued research and development remain paramount. Focus areas include enhancing lifecycle assessments, improving recycling technologies, and developing bio-based PVC materials that further decrease environmental impacts. By prioritizing innovation, the PVC industry is poised to meet future challenges, maintaining its position as an indispensable material in global manufacturing. In conclusion, the PVC production industry embodies a blend of technical expertise and adaptive strategies, ensuring consistent output of high-quality materials suited for a wide array of applications. Its ongoing evolution, characterized by sustainable practices and technological advancements, highlights the industry's dedication to not only meeting current demands but also anticipating future needs, solidifying its role as a pivotal component of modern industrial practice.

Authoritative research stresses PVC’s role in energy conservation. Owing to its thermal insulation properties, rigid PVC materials are instrumental in creating energy-efficient building solutions. This facet not only underscores the material's functional benefits but also its critical role in supporting global sustainability goals. Trusted institutions report that utilizing PVC in construction substantially contributes to reduced energy consumption, highlighting its importance in modern energy-efficient building design. The credibility of the PVC industry is further enhanced by rigorous standards and certifications, which govern every aspect of production, from raw material sourcing to final product output. Regulatory bodies worldwide enforce these standards, ensuring that PVC products meet strict safety and performance criteria. Compliance with such regulations not only builds trust with consumers but also reinforces the industry’s reputation for reliability and responsibility. As the industry progresses, continued research and development remain paramount. Focus areas include enhancing lifecycle assessments, improving recycling technologies, and developing bio-based PVC materials that further decrease environmental impacts. By prioritizing innovation, the PVC industry is poised to meet future challenges, maintaining its position as an indispensable material in global manufacturing. In conclusion, the PVC production industry embodies a blend of technical expertise and adaptive strategies, ensuring consistent output of high-quality materials suited for a wide array of applications. Its ongoing evolution, characterized by sustainable practices and technological advancements, highlights the industry's dedication to not only meeting current demands but also anticipating future needs, solidifying its role as a pivotal component of modern industrial practice.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025