2 月 . 20, 2025 00:53

Back to list

pvc price kg

Navigating the Complex World of PVC Pricing An Insider's Guide

The competitive landscape in the PVC market should also be considered. Market demand, customer preferences, and competitor strategies interact to influence prices. For producers, understanding the balance between scaling operations to achieve cost efficiencies and maintaining product quality is paramount. With a discernible tilt towards sustainable and environmentally friendly options, many consumers are willing to pay a premium, potentially affecting the price per kilogram of PVC. Technological advancements continue to offer innovative solutions within the PVC industry, further complicating the pricing structure. The integration of automation and AI in manufacturing processes not only boosts production efficiency but also allows for precision in managing resource allocation. This technological embrace translates into consistent product quality and price stabilization, reinforcing trust among consumers and stakeholders alike. Reflecting on these elements, forecasting future PVC prices per kilogram involves an amalgamation of economic projections, raw material data analysis, and geopolitical assessments. For stakeholders, adopting a comprehensive approach that meticulously considers these factors is essential for making informed decisions. As the demand for construction and infrastructure development grows globally, staying informed about the factors influencing PVC pricing remains crucial for businesses seeking to optimize costs and maximize profitability. Finally, the role of sustainable development and corporate responsibility in shaping future pricing strategies cannot be overstated. As regulations tighten around environmental protection and corporate footprints, the PVC industry is expected to adapt by investing in greener technologies and practices, undoubtedly influencing future cost structures. In conclusion, PVC pricing per kilogram is a multifaceted issue woven from diverse threads of raw material costs, production technologies, supply chain dynamics, and global economic factors. By embracing an integrated approach that combines real-world experience, expert knowledge, and authoritative resources, industry players can navigate this landscape with confidence, ensuring both competitiveness and sustainability in their operations.

The competitive landscape in the PVC market should also be considered. Market demand, customer preferences, and competitor strategies interact to influence prices. For producers, understanding the balance between scaling operations to achieve cost efficiencies and maintaining product quality is paramount. With a discernible tilt towards sustainable and environmentally friendly options, many consumers are willing to pay a premium, potentially affecting the price per kilogram of PVC. Technological advancements continue to offer innovative solutions within the PVC industry, further complicating the pricing structure. The integration of automation and AI in manufacturing processes not only boosts production efficiency but also allows for precision in managing resource allocation. This technological embrace translates into consistent product quality and price stabilization, reinforcing trust among consumers and stakeholders alike. Reflecting on these elements, forecasting future PVC prices per kilogram involves an amalgamation of economic projections, raw material data analysis, and geopolitical assessments. For stakeholders, adopting a comprehensive approach that meticulously considers these factors is essential for making informed decisions. As the demand for construction and infrastructure development grows globally, staying informed about the factors influencing PVC pricing remains crucial for businesses seeking to optimize costs and maximize profitability. Finally, the role of sustainable development and corporate responsibility in shaping future pricing strategies cannot be overstated. As regulations tighten around environmental protection and corporate footprints, the PVC industry is expected to adapt by investing in greener technologies and practices, undoubtedly influencing future cost structures. In conclusion, PVC pricing per kilogram is a multifaceted issue woven from diverse threads of raw material costs, production technologies, supply chain dynamics, and global economic factors. By embracing an integrated approach that combines real-world experience, expert knowledge, and authoritative resources, industry players can navigate this landscape with confidence, ensuring both competitiveness and sustainability in their operations.

Prev:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

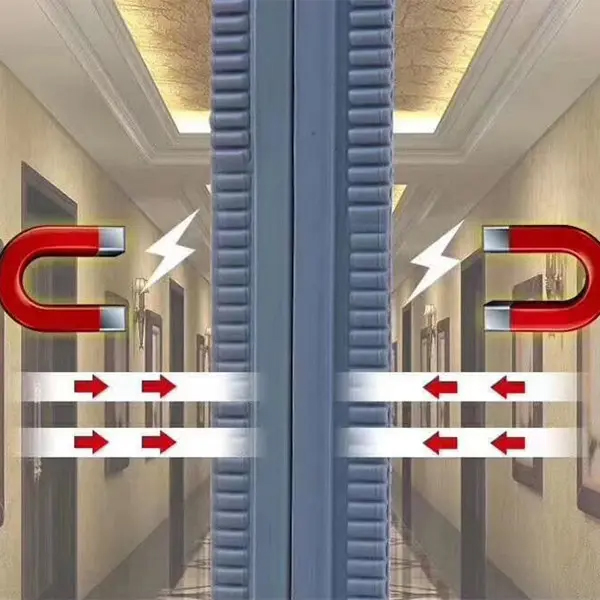

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025