2 月 . 12, 2025 19:57

Back to list

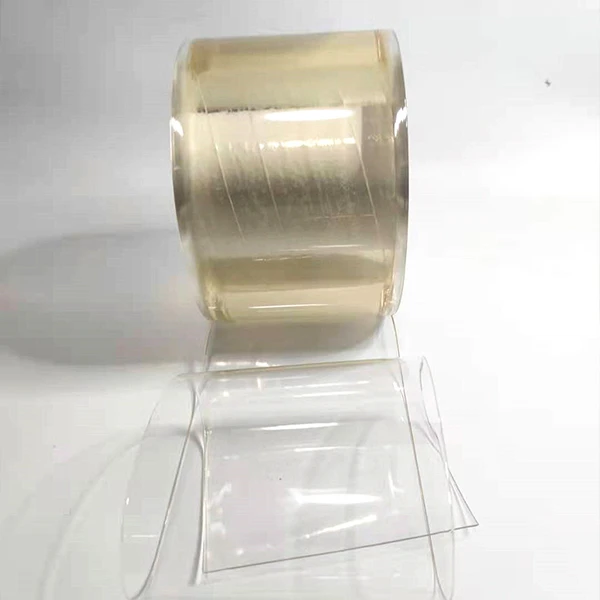

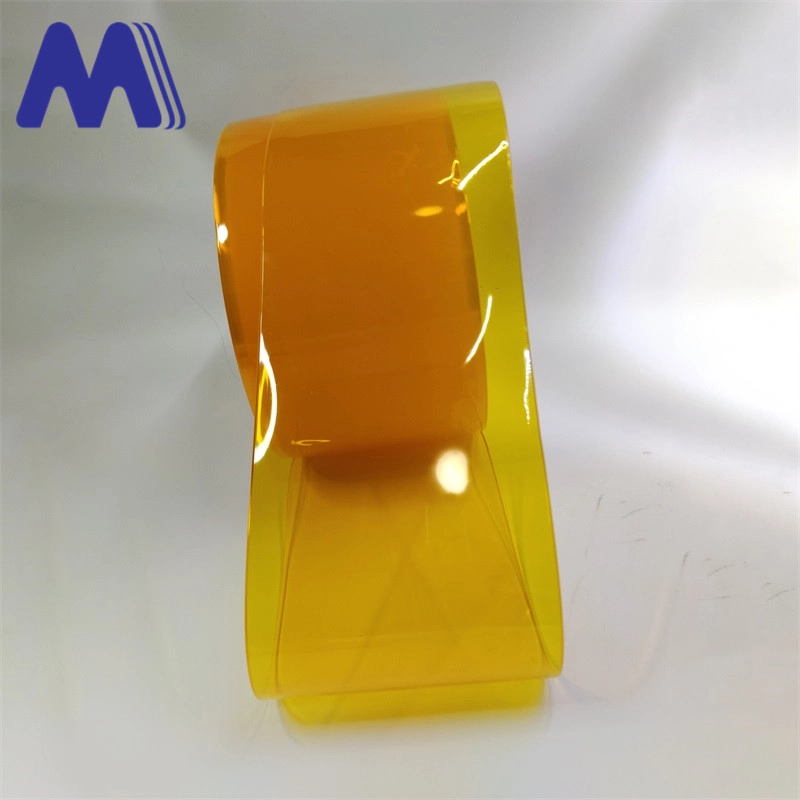

pvc plastic strip curtain

PVC plastic strip curtains are indispensable assets in numerous industrial and commercial settings, offering both functional and financial benefits. Their high durability, flexibility, and transparency make them particularly prized in environments that require controlled separation, such as warehouses, restaurants, and cold storage facilities. Drawing from both our deep-seated expertise and extensive industry analysis, this article elucidates their multifaceted advantages.

The sustainability aspect of PVC plastic strip curtains cannot be sidelined. Modern manufacturing processes are increasingly emphasizing environmentally friendly materials. High-quality PVC curtains are now recyclable, reducing their ecological impact. This aligns well with global corporate responsibility trends where businesses are under pressure to adopt sustainable practices. When selecting PVC strip curtains, it is imperative to engage with trusted suppliers who can offer tailored solutions. Expert consultation should consider specific site requirements such as thickness, overlap, and mounting methods. Advanced technologies in PVC material can even enhance UV resistance and anti-static characteristics, making them suitable for more specialized applications. Proper installation and maintenance prolong the lifespan of these curtains, reaffirming their cost-effectiveness. Regular cleaning, for instance, mitigates material degradation and maintains optimal transparency, ensuring that they remain functional over extended periods. Engaging professional services for installation can also avert common pitfalls, such as misalignment and inadequate sealing, which could compromise their performance. In conclusion, PVC plastic strip curtains embody a perfect confluence of utility, efficiency, and sustainability. Their strategic implementation is a testament to an establishment's commitment to operational excellence and environmental responsibility. As industry leaders continue to seek innovative solutions to everyday challenges, integrating PVC strip curtains into business operations emerges not only as a beneficial option but often a necessary one.

The sustainability aspect of PVC plastic strip curtains cannot be sidelined. Modern manufacturing processes are increasingly emphasizing environmentally friendly materials. High-quality PVC curtains are now recyclable, reducing their ecological impact. This aligns well with global corporate responsibility trends where businesses are under pressure to adopt sustainable practices. When selecting PVC strip curtains, it is imperative to engage with trusted suppliers who can offer tailored solutions. Expert consultation should consider specific site requirements such as thickness, overlap, and mounting methods. Advanced technologies in PVC material can even enhance UV resistance and anti-static characteristics, making them suitable for more specialized applications. Proper installation and maintenance prolong the lifespan of these curtains, reaffirming their cost-effectiveness. Regular cleaning, for instance, mitigates material degradation and maintains optimal transparency, ensuring that they remain functional over extended periods. Engaging professional services for installation can also avert common pitfalls, such as misalignment and inadequate sealing, which could compromise their performance. In conclusion, PVC plastic strip curtains embody a perfect confluence of utility, efficiency, and sustainability. Their strategic implementation is a testament to an establishment's commitment to operational excellence and environmental responsibility. As industry leaders continue to seek innovative solutions to everyday challenges, integrating PVC strip curtains into business operations emerges not only as a beneficial option but often a necessary one.

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025