1 月 . 20, 2025 15:55

Back to list

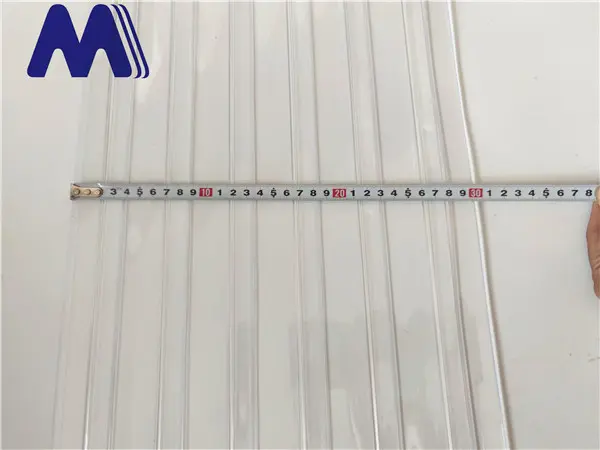

High Quality Stainless Steel Strip Hanger Curtain Rail

PVC plastic sheet rolls have long been celebrated in various industries for their versatility and durability. As an expert in materials and construction, I often come across inquiries regarding the efficiency, applications, and environmental impact of PVC plastic sheet rolls. Let's delve deeper into understanding why these sheets stand out in the world of polymers.

The eco-friendliness of PVC plastic sheet rolls is often questioned, yet they rank high in sustainability when evaluated on a lifecycle basis. Modern PVC materials are increasingly manufactured with a focus on recyclability and reduced environmental impact. Many manufacturers today have embraced recycling programs that repurpose these sheets, minimizing landfill waste and conserving resources. Energy efficiency is another notable attribute of PVC plastic sheet rolls. When used in construction or insulation, these sheets contribute to reducing energy consumption by providing excellent thermal resistance. This property not only aids in maintaining desired temperature levels but also reduces dependency on heating and cooling systems, thereby lowering energy bills and carbon footprint. From an aesthetic perspective, PVC plastic sheet rolls do not fall short either. Available in a range of colors and finishes, they offer design flexibility that can enhance the visual appeal of any application, be it cladding a building façade or serving as decorative partitions in an office. Their ability to be printed on or colored also adds an extra layer of personalization, making them suitable for branding and marketing purposes. In conclusion, PVC plastic sheet rolls continue to play a pivotal role across various sectors. Their blend of durability, flexibility, resistance, and eco-friendliness ensures their relevance and reliability in meeting modern-day demands. As industries evolve, so does the sophistication of these materials, underscoring the importance of choosing PVC plastic sheet rolls for projects that demand excellence and sustainability. With a clear understanding of their benefits, businesses can better leverage these sheets to achieve their operational and environmental goals. As more advancements are made in material technology, it is certain that PVC plastic sheet rolls will continue to be an essential asset in numerous applications.

The eco-friendliness of PVC plastic sheet rolls is often questioned, yet they rank high in sustainability when evaluated on a lifecycle basis. Modern PVC materials are increasingly manufactured with a focus on recyclability and reduced environmental impact. Many manufacturers today have embraced recycling programs that repurpose these sheets, minimizing landfill waste and conserving resources. Energy efficiency is another notable attribute of PVC plastic sheet rolls. When used in construction or insulation, these sheets contribute to reducing energy consumption by providing excellent thermal resistance. This property not only aids in maintaining desired temperature levels but also reduces dependency on heating and cooling systems, thereby lowering energy bills and carbon footprint. From an aesthetic perspective, PVC plastic sheet rolls do not fall short either. Available in a range of colors and finishes, they offer design flexibility that can enhance the visual appeal of any application, be it cladding a building façade or serving as decorative partitions in an office. Their ability to be printed on or colored also adds an extra layer of personalization, making them suitable for branding and marketing purposes. In conclusion, PVC plastic sheet rolls continue to play a pivotal role across various sectors. Their blend of durability, flexibility, resistance, and eco-friendliness ensures their relevance and reliability in meeting modern-day demands. As industries evolve, so does the sophistication of these materials, underscoring the importance of choosing PVC plastic sheet rolls for projects that demand excellence and sustainability. With a clear understanding of their benefits, businesses can better leverage these sheets to achieve their operational and environmental goals. As more advancements are made in material technology, it is certain that PVC plastic sheet rolls will continue to be an essential asset in numerous applications.

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025