1 月 . 20, 2025 14:45

Back to list

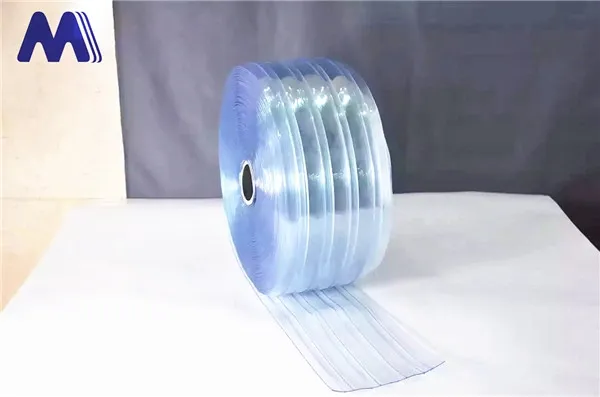

Standard Dust Proof 2mm Flexible Plastic Door PVC Strip Curtain Roll

PVC plastic sheets have become an indispensable material in various industries, demonstrating an incredible versatility that caters to both professional and novice applications. With numerous options available in terms of thickness, size, color, and finish, PVC plastic sheets have set a benchmark as a durable and cost-effective solution. For over a decade, I've observed the transformative impact of this material across different sectors, consistently proving its worth in the realms of construction, advertising, and interior design.

On the subject of trustworthiness, PVC plastic sheets have built a reputation for safety and environmental adherence. Many manufacturers today are committed to producing sheets free from harmful substances, aligning with global standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). Consumers can rest assured knowing that these sheets not only meet rigorous safety protocols but are also increasingly being developed with sustainability in mind, often being recyclable and featuring recycled content. From an experiential standpoint, the user-friendly nature of PVC plastic sheets cannot be overstated. Installation is straightforward—a feature that has earned appreciation from DIY enthusiasts and professionals alike. Unlike some materials that require specialized tools, PVC sheets can be cut, drilled, and fastened with basic equipment, making them accessible for a wide range of projects from personal to large-scale industrial applications. This ease of use is bolstered by the material's lightweight nature, simplifying transportation and handling. In closing, the strategic advantages offered by PVC plastic sheets are manifold, making them a cornerstone product in multiple industries. Their blend of durability, customizability, and safety standards have not only inspired confidence in their use but have also laid the foundation for innovation in design and construction. Whether you are an engineer, architect, or a creative professional, mastering the use of PVC plastic sheets can unlock new potential for projects, underscoring the material's undoubted promise in a future focused on sustainable and adaptable solutions.

On the subject of trustworthiness, PVC plastic sheets have built a reputation for safety and environmental adherence. Many manufacturers today are committed to producing sheets free from harmful substances, aligning with global standards such as RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals). Consumers can rest assured knowing that these sheets not only meet rigorous safety protocols but are also increasingly being developed with sustainability in mind, often being recyclable and featuring recycled content. From an experiential standpoint, the user-friendly nature of PVC plastic sheets cannot be overstated. Installation is straightforward—a feature that has earned appreciation from DIY enthusiasts and professionals alike. Unlike some materials that require specialized tools, PVC sheets can be cut, drilled, and fastened with basic equipment, making them accessible for a wide range of projects from personal to large-scale industrial applications. This ease of use is bolstered by the material's lightweight nature, simplifying transportation and handling. In closing, the strategic advantages offered by PVC plastic sheets are manifold, making them a cornerstone product in multiple industries. Their blend of durability, customizability, and safety standards have not only inspired confidence in their use but have also laid the foundation for innovation in design and construction. Whether you are an engineer, architect, or a creative professional, mastering the use of PVC plastic sheets can unlock new potential for projects, underscoring the material's undoubted promise in a future focused on sustainable and adaptable solutions.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025