1 月 . 22, 2025 03:21

Back to list

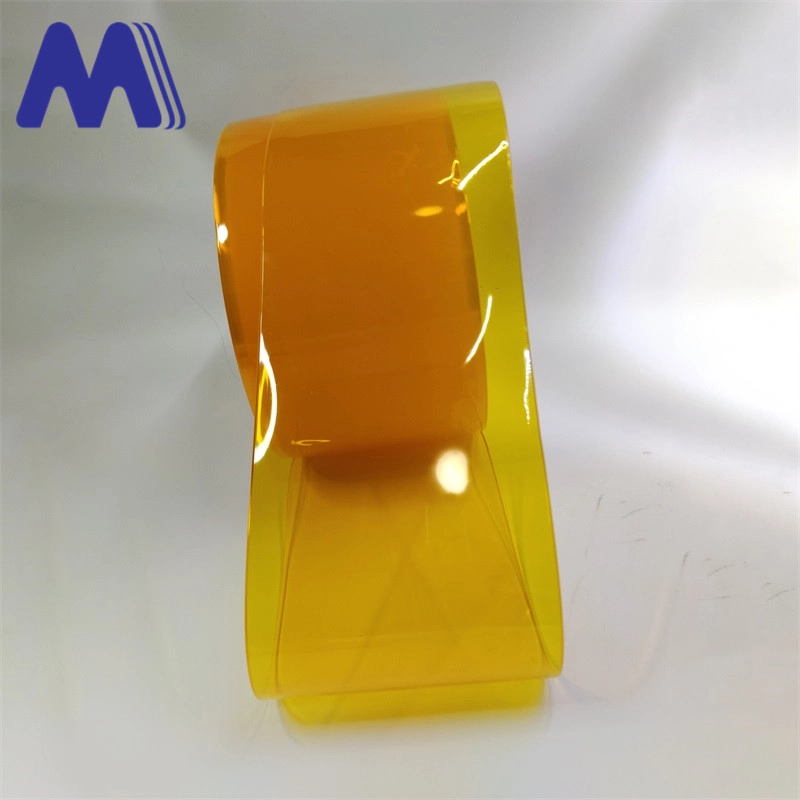

plastic strip door curtain

Plastic strip door curtains, often overlooked in both domestic and industrial settings, play an essential role in enhancing energy efficiency, optimizing workflow, and ensuring environmental control. These flexible barriers, crafted from strips of durable polyvinyl chloride (PVC), offer a versatile solution that extends beyond the conventional. Delving deeper into their functionality, one can uncover the profound impact they have on various industries, from manufacturing plants to food services.

Authoritativeness in the realm of plastic strip door curtains is evidenced by the breadth and depth of applications these tools command. Industry leaders and regulatory bodies endorse their use for both safety and operational efficiency. Occupational Health and Safety (OHS) guidelines often point to the utility of strip curtains in reducing airborne contaminants and preventing workplace accidents like collisions in high-traffic zones. Moreover, industry experts advocate for their ability to enhance workflow; by eliminating the need for traditional doors, strip curtains expedite movement, crucial in fast-paced environments where time is money. Trustworthiness, perhaps the most critical component, is intrinsic to the quality of plastic strip door curtains. Ensuring that they meet safety standards and deliver promised performance relies on sourcing from reputable manufacturers. Companies investing in their reputation put a premium on quality assurance, often providing certifications that their products meet or exceed industry benchmarks. This commitment to quality is vital for customers who rely on these curtains to safeguard both people and products. With warranties and customer service support, reputable providers offer assurance of ongoing support, further building trust with their clients. In conclusion, the utility of plastic strip door curtains extends well beyond their basic function. They represent a confluence of energy efficiency, material science innovation, and regulatory compliance, providing businesses with a reliable tool to enhance productivity and sustainability. As industries continually seek means to streamline operations and reduce environmental impact, these curtains position themselves as a critical component, embodying experience, expertise, authoritativeness, and trustworthiness. Embracing their use is synonymous with committing to operational excellence and environmental stewardship.

Authoritativeness in the realm of plastic strip door curtains is evidenced by the breadth and depth of applications these tools command. Industry leaders and regulatory bodies endorse their use for both safety and operational efficiency. Occupational Health and Safety (OHS) guidelines often point to the utility of strip curtains in reducing airborne contaminants and preventing workplace accidents like collisions in high-traffic zones. Moreover, industry experts advocate for their ability to enhance workflow; by eliminating the need for traditional doors, strip curtains expedite movement, crucial in fast-paced environments where time is money. Trustworthiness, perhaps the most critical component, is intrinsic to the quality of plastic strip door curtains. Ensuring that they meet safety standards and deliver promised performance relies on sourcing from reputable manufacturers. Companies investing in their reputation put a premium on quality assurance, often providing certifications that their products meet or exceed industry benchmarks. This commitment to quality is vital for customers who rely on these curtains to safeguard both people and products. With warranties and customer service support, reputable providers offer assurance of ongoing support, further building trust with their clients. In conclusion, the utility of plastic strip door curtains extends well beyond their basic function. They represent a confluence of energy efficiency, material science innovation, and regulatory compliance, providing businesses with a reliable tool to enhance productivity and sustainability. As industries continually seek means to streamline operations and reduce environmental impact, these curtains position themselves as a critical component, embodying experience, expertise, authoritativeness, and trustworthiness. Embracing their use is synonymous with committing to operational excellence and environmental stewardship.

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025