2 月 . 20, 2025 07:57

Back to list

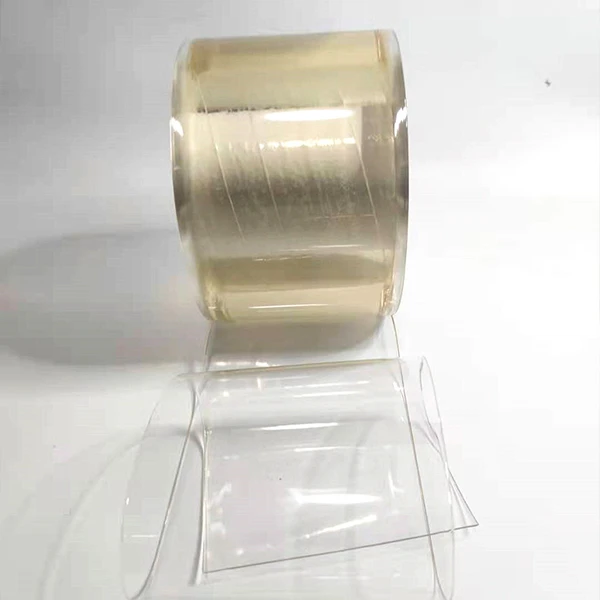

Freezer Curtain Strips

Plastic curtain strips, often overshadowed by their industrial utility, have silently revolutionized workplaces and commercial spaces worldwide. These strips, composed predominantly of flexible PVC, offer a blend of simplicity and sophistication, transforming environments in ways that are both subtle and profound.

The authoritativeness of plastic curtain strips as a solution is evident from their widespread adoption in industries ranging from food processing to pharmaceuticals, logistics, and beyond. Their implementation adheres to stringent regulations and standards, ensuring both safety and efficiency. For example, in the food industry, where hygiene and contamination prevention are critical, plastic strips are manufactured to comply with USDA and FDA guidelines, underscoring their reliability and compliance with health standards. Trustworthiness in the context of plastic curtain strips is built on their proven track record. Decades of deployment have demonstrated their effectiveness, with countless testimonials from businesses attesting to cost savings, operational efficiency, and enhanced safety standards. Manufacturers often provide detailed certifications and warranties, reinforcing customer confidence in the product’s longevity and performance. Furthermore, the sustainability aspect of plastic curtain strips is gaining recognition. Advances in recycling techniques and the development of eco-friendly materials are paving the way for more sustainable production practices. This focus on environmental responsibility aligns with a growing global demand for solutions that minimize ecological impact, making plastic curtain strips not only a practical choice but a conscientious one. In conclusion, plastic curtain strips, with their unassuming presence, bring about transformative benefits across industries. Their distinctive combination of visibility, flexibility, and environmental control positions them as indispensable tools in modern business operations. The synergy of experience, expertise, authoritativeness, and trustworthiness encapsulates their enduring appeal and effectiveness. Companies seeking efficiency and innovation find a reliable partner in these versatile strips, ensuring that their utility will continue to thrive in the evolving landscapes of global industries.

The authoritativeness of plastic curtain strips as a solution is evident from their widespread adoption in industries ranging from food processing to pharmaceuticals, logistics, and beyond. Their implementation adheres to stringent regulations and standards, ensuring both safety and efficiency. For example, in the food industry, where hygiene and contamination prevention are critical, plastic strips are manufactured to comply with USDA and FDA guidelines, underscoring their reliability and compliance with health standards. Trustworthiness in the context of plastic curtain strips is built on their proven track record. Decades of deployment have demonstrated their effectiveness, with countless testimonials from businesses attesting to cost savings, operational efficiency, and enhanced safety standards. Manufacturers often provide detailed certifications and warranties, reinforcing customer confidence in the product’s longevity and performance. Furthermore, the sustainability aspect of plastic curtain strips is gaining recognition. Advances in recycling techniques and the development of eco-friendly materials are paving the way for more sustainable production practices. This focus on environmental responsibility aligns with a growing global demand for solutions that minimize ecological impact, making plastic curtain strips not only a practical choice but a conscientious one. In conclusion, plastic curtain strips, with their unassuming presence, bring about transformative benefits across industries. Their distinctive combination of visibility, flexibility, and environmental control positions them as indispensable tools in modern business operations. The synergy of experience, expertise, authoritativeness, and trustworthiness encapsulates their enduring appeal and effectiveness. Companies seeking efficiency and innovation find a reliable partner in these versatile strips, ensuring that their utility will continue to thrive in the evolving landscapes of global industries.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025