1 月 . 22, 2025 05:15

Back to list

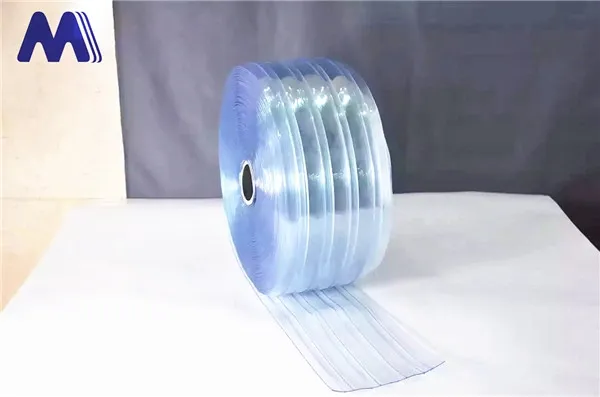

pvc clear door curtain Anti-Static Pvc Strip Curtain plastic roll

Industrial PVC curtains have transformed environments across various industries by offering a cost-effective solution to multiple operational challenges. Their adaptability and robustness play a crucial role in manufacturing, food processing, warehousing, and commercial sectors, meeting the dual needs of accessibility and environmental control.

Environment-friendliness of materials used in production has become a significant consideration in contemporary industry operations. Responsible manufacturers are increasingly adopting recyclable and phthalate-free materials for their PVC curtains. This commitment not only aligns with global sustainable practices but also enhances the corporate social responsibility profiles of businesses deploying these curtains. By choosing suppliers who prioritize sustainability, businesses bolster their own credibility in a market that increasingly values green initiatives. From a trustworthiness perspective, testimonials and case studies from leading businesses underline the efficacy of PVC curtains. Many companies report substantial cost savings, reduced energy expenses, and heightened operational efficiency following the installation of these curtains. By integrating feedback and continuous improvements, reputable manufacturers work collaboratively with clients to customize solutions tailored to specific environmental needs. Lastly, installing PVC curtains is relatively straightforward, with numerous companies offering installation services as part of full-service packages. This is particularly beneficial for businesses seeking to minimize operational disruptions. Reputable suppliers often provide on-site assessments, ensuring that the curtain systems are precisely tailored to the architectural and operational requirements of the facility. In summary, industrial PVC curtains provide multidimensional benefits across diverse industries. Their contribution to operational efficiency, environmental separation, and cost savings is undisputed. By selecting high-quality products from reputable suppliers, businesses can enhance their operational capacity while adhering to environmental and safety standards. As industries continue to adapt to changing needs and regulatory landscapes, PVC curtains stand out as a versatile solution, offering unmatched reliability and performance.

Environment-friendliness of materials used in production has become a significant consideration in contemporary industry operations. Responsible manufacturers are increasingly adopting recyclable and phthalate-free materials for their PVC curtains. This commitment not only aligns with global sustainable practices but also enhances the corporate social responsibility profiles of businesses deploying these curtains. By choosing suppliers who prioritize sustainability, businesses bolster their own credibility in a market that increasingly values green initiatives. From a trustworthiness perspective, testimonials and case studies from leading businesses underline the efficacy of PVC curtains. Many companies report substantial cost savings, reduced energy expenses, and heightened operational efficiency following the installation of these curtains. By integrating feedback and continuous improvements, reputable manufacturers work collaboratively with clients to customize solutions tailored to specific environmental needs. Lastly, installing PVC curtains is relatively straightforward, with numerous companies offering installation services as part of full-service packages. This is particularly beneficial for businesses seeking to minimize operational disruptions. Reputable suppliers often provide on-site assessments, ensuring that the curtain systems are precisely tailored to the architectural and operational requirements of the facility. In summary, industrial PVC curtains provide multidimensional benefits across diverse industries. Their contribution to operational efficiency, environmental separation, and cost savings is undisputed. By selecting high-quality products from reputable suppliers, businesses can enhance their operational capacity while adhering to environmental and safety standards. As industries continue to adapt to changing needs and regulatory landscapes, PVC curtains stand out as a versatile solution, offering unmatched reliability and performance.

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025