2 月 . 15, 2025 13:43

Back to list

Curtain

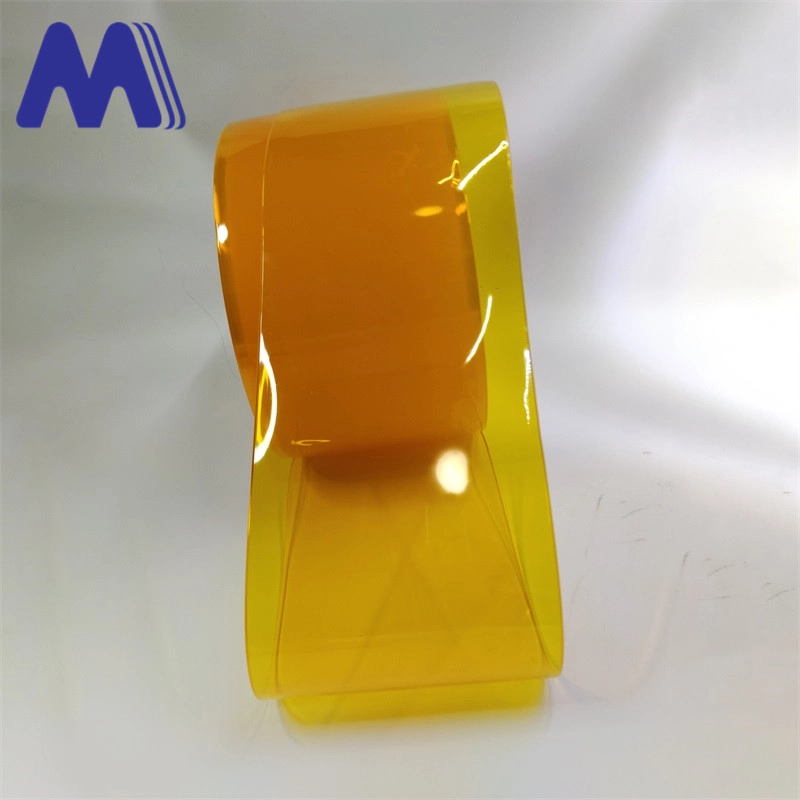

Industrial curtains, often overlooked yet incredibly valuable, have revolutionized numerous sectors by enhancing operational efficiency and safety. Typically constructed from durable materials such as vinyl, these curtains serve as flexible barriers in various environments. They find application in warehouses, factories, and even retail spaces, proving essential for many reasons.

Beyond their primary functions, industrial curtains offer versatility that extends their usefulness. In automotive workshops, for example, these curtains can serve as dividers between different workstations, ensuring that tasks such as painting and welding can occur simultaneously without cross-contamination. This adaptability is a testament to the innovative design strategies employed by manufacturers who continually evolve these products to meet dynamic industrial needs. Incorporating industrial curtains into a business’s operational framework is more than a practical decision; it’s a strategic move. As industries continue to prioritize safety and efficiency, the role of such curtains becomes increasingly significant. They not only optimize workflow by creating dedicated zones for different processes but also enhance environmental conditions by controlling dust and fumes, thereby contributing to the overall well-being of employees. For businesses contemplating the integration of industrial curtains, collaboration with reputable suppliers is crucial. These experts provide invaluable insight into the customization of solutions tailored to specific spatial requirements. Their expertise ensures that businesses capitalize on the full potential of these curtains, aligning with organizational goals such as sustainability and increased productivity. In conclusion, industrial curtains are indispensable tools that embody both practicality and innovation. By addressing a wide spectrum of operational challenges—from noise reduction to temperature control—they play a pivotal role in fostering safer, more efficient work environments. Their enduring relevance and versatility make them a worthy investment for any business looking to enhance its operational infrastructure while simultaneously prioritizing employee welfare.

Beyond their primary functions, industrial curtains offer versatility that extends their usefulness. In automotive workshops, for example, these curtains can serve as dividers between different workstations, ensuring that tasks such as painting and welding can occur simultaneously without cross-contamination. This adaptability is a testament to the innovative design strategies employed by manufacturers who continually evolve these products to meet dynamic industrial needs. Incorporating industrial curtains into a business’s operational framework is more than a practical decision; it’s a strategic move. As industries continue to prioritize safety and efficiency, the role of such curtains becomes increasingly significant. They not only optimize workflow by creating dedicated zones for different processes but also enhance environmental conditions by controlling dust and fumes, thereby contributing to the overall well-being of employees. For businesses contemplating the integration of industrial curtains, collaboration with reputable suppliers is crucial. These experts provide invaluable insight into the customization of solutions tailored to specific spatial requirements. Their expertise ensures that businesses capitalize on the full potential of these curtains, aligning with organizational goals such as sustainability and increased productivity. In conclusion, industrial curtains are indispensable tools that embody both practicality and innovation. By addressing a wide spectrum of operational challenges—from noise reduction to temperature control—they play a pivotal role in fostering safer, more efficient work environments. Their enduring relevance and versatility make them a worthy investment for any business looking to enhance its operational infrastructure while simultaneously prioritizing employee welfare.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025