2 月 . 02, 2025 04:09

Back to list

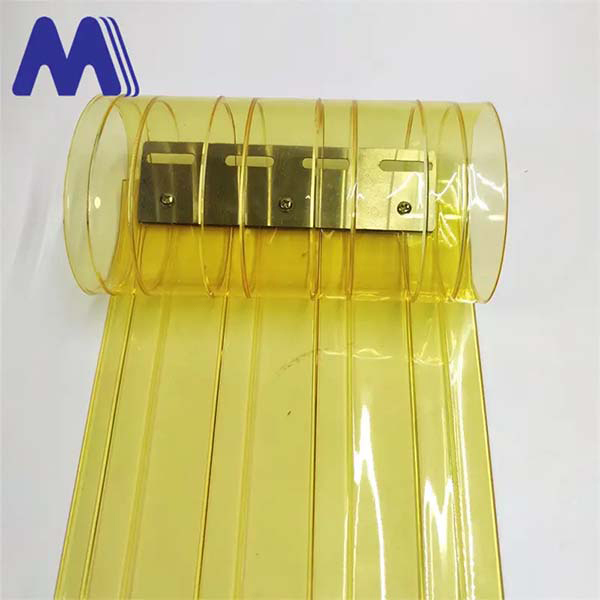

transparent PVC strip curtain rolls

Industrial curtains have emerged as indispensable tools in modern manufacturing and service industries, providing an array of benefits that enhance operational efficiency and safety. With technology continuously advancing, these curtains now boast features tailored to meet the demands of various industrial environments. Below is a comprehensive exploration of why industrial curtains have become pivotal in industrial settings, drawing on real-world experiences and expert insights to highlight their esteemed value.

From an expertise standpoint, it’s essential to recognize the diversity in materials and designs available for industrial curtains. High-quality PVC, reinforced vinyl, and hypoallergenic materials are among the options tailored to specific industry needs. For instance, food processing industries often opt for curtains made from anti-microbial materials to maintain hygiene standards. Customization options, such as anti-UV protection and soundproofing, further increase their application across diverse industries, including pharmaceuticals, aerospace, and logistics. Authoritative reviews from industry experts underscore the durability and longevity of high-grade industrial curtains. Unlike traditional materials which may require frequent maintenance or replacement, well-crafted curtains are designed for durability, with some brands offering warranties that attest to their long-term reliability. Furthermore, their modular nature allows for easy repair or replacement of sections, minimizing downtime and maintenance expenditures. Trustworthiness in the product’s performance is enhanced through third-party certifications and compliance with industry standards. Many manufacturers rigorously test their products to align with ISO standards, ensuring curtains meet or exceed safety and performance benchmarks. This commitment to quality is pivotal in fostering trust among businesses seeking reliable solutions for their dynamic operational environments. In conclusion, the rise of industrial curtains as a staple in the manufacturing and service sectors speaks volumes of their utility and adaptability. Rooted in real-world success stories and supported by a wealth of expertise, industrial curtains are trusted solutions that combine practicality with cost efficiency. Their evolution reflects the progress of industrial technology in accommodating safety, environmental, and operational needs — an evolution that promises further innovations in years to come.

From an expertise standpoint, it’s essential to recognize the diversity in materials and designs available for industrial curtains. High-quality PVC, reinforced vinyl, and hypoallergenic materials are among the options tailored to specific industry needs. For instance, food processing industries often opt for curtains made from anti-microbial materials to maintain hygiene standards. Customization options, such as anti-UV protection and soundproofing, further increase their application across diverse industries, including pharmaceuticals, aerospace, and logistics. Authoritative reviews from industry experts underscore the durability and longevity of high-grade industrial curtains. Unlike traditional materials which may require frequent maintenance or replacement, well-crafted curtains are designed for durability, with some brands offering warranties that attest to their long-term reliability. Furthermore, their modular nature allows for easy repair or replacement of sections, minimizing downtime and maintenance expenditures. Trustworthiness in the product’s performance is enhanced through third-party certifications and compliance with industry standards. Many manufacturers rigorously test their products to align with ISO standards, ensuring curtains meet or exceed safety and performance benchmarks. This commitment to quality is pivotal in fostering trust among businesses seeking reliable solutions for their dynamic operational environments. In conclusion, the rise of industrial curtains as a staple in the manufacturing and service sectors speaks volumes of their utility and adaptability. Rooted in real-world success stories and supported by a wealth of expertise, industrial curtains are trusted solutions that combine practicality with cost efficiency. Their evolution reflects the progress of industrial technology in accommodating safety, environmental, and operational needs — an evolution that promises further innovations in years to come.

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025