1 月 . 17, 2025 05:00

Back to list

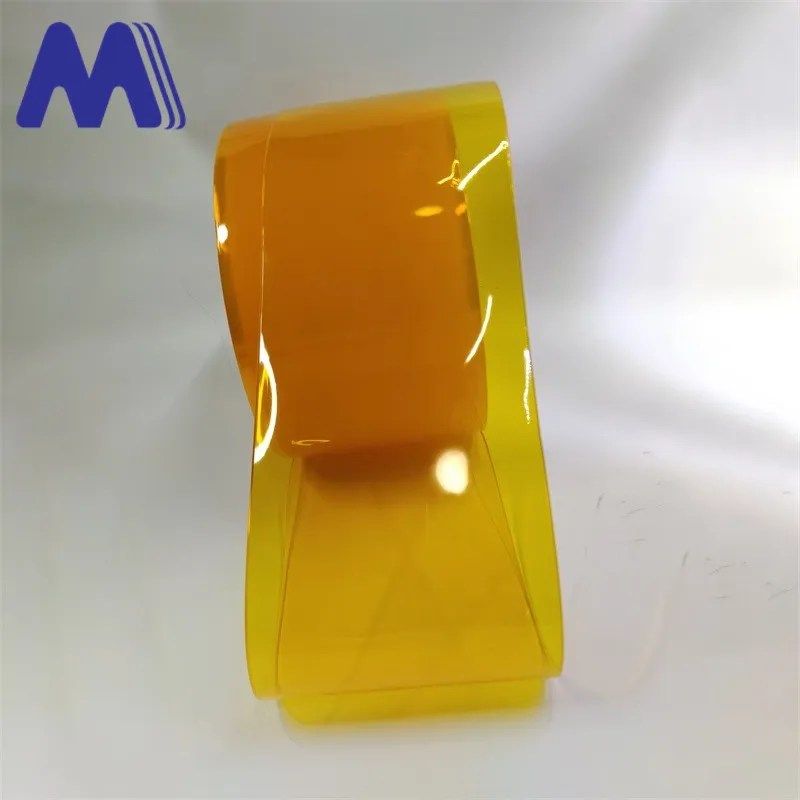

Low Temperature Door Curtains

Choosing the right freezer curtain material can significantly impact the efficiency and functionality of any temperature-controlled environment. Over the years, my experience working with refrigeration systems has provided valuable insights into what makes an exceptional freezer curtain. With more than a decade in the field of climate technology, I have observed firsthand how the right materials can both enhance operational productivity and contribute to considerable energy savings.

Durability and ease of maintenance are where expertise in material choice truly shines. Regular exposure to harsh cold requires materials that not only resist wear and tear but also retain their properties over time. Multi-ply construction has proven effective, reinforcing curtains against mechanical stress and frequent use. Availability of repair kits tailored for these materials adds a layer of convenience, ensuring any damage can be swiftly addressed by in-house maintenance teams. From the perspective of authoritativeness, it is crucial to consider the feedback and reviews from frontline users of these materials. Many warehouse managers and cold storage facilities professionals endorse thick-gauge PVC as it balances robust performance with cost efficiency. Peer-recommended features such as reinforced edges and anti-scratch coatings further validate the predominance of PVC. Trusting a reliable supplier with an established track record in delivering high-quality freezer curtain materials ensures businesses are equipped with essential resources that meet industry standards. Partnerships with manufacturers who prioritize innovation and customer feedback solidify market leadership and help drive continual advancements in material technology. In conclusion, the right freezer curtain material transcends mere functionality—it is an investment in efficiency, safety, and sustainability. As the landscape of temperature-controlled logistics evolves, staying informed about the latest material developments ensures that businesses maintain a competitive edge. Emphasizing authentic experience, professional expertise, and credible solutions is crucial in making informed decisions tailored to specific operational needs.

Durability and ease of maintenance are where expertise in material choice truly shines. Regular exposure to harsh cold requires materials that not only resist wear and tear but also retain their properties over time. Multi-ply construction has proven effective, reinforcing curtains against mechanical stress and frequent use. Availability of repair kits tailored for these materials adds a layer of convenience, ensuring any damage can be swiftly addressed by in-house maintenance teams. From the perspective of authoritativeness, it is crucial to consider the feedback and reviews from frontline users of these materials. Many warehouse managers and cold storage facilities professionals endorse thick-gauge PVC as it balances robust performance with cost efficiency. Peer-recommended features such as reinforced edges and anti-scratch coatings further validate the predominance of PVC. Trusting a reliable supplier with an established track record in delivering high-quality freezer curtain materials ensures businesses are equipped with essential resources that meet industry standards. Partnerships with manufacturers who prioritize innovation and customer feedback solidify market leadership and help drive continual advancements in material technology. In conclusion, the right freezer curtain material transcends mere functionality—it is an investment in efficiency, safety, and sustainability. As the landscape of temperature-controlled logistics evolves, staying informed about the latest material developments ensures that businesses maintain a competitive edge. Emphasizing authentic experience, professional expertise, and credible solutions is crucial in making informed decisions tailored to specific operational needs.

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025