2 月 . 18, 2025 07:26

Back to list

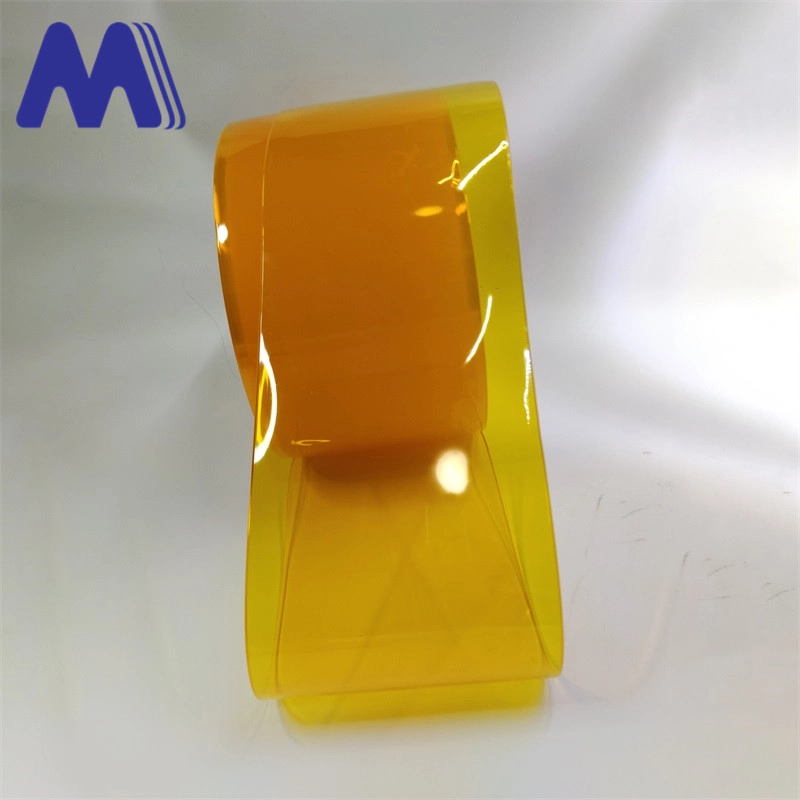

flexible plastic sheet

The world of flexible plastic sheets offers an array of benefits that extend across multiple industries, making them a versatile choice for manufacturers, DIY enthusiasts, and innovators alike. These sheets, crafted from materials such as polyethylene, polypropylene, and PET, have garnered significant attention for their adaptability, durability, and economic advantages.

One cannot overlook the economic benefits of incorporating flexible plastic sheets into operations. Due to their lightweight nature, transportation costs are significantly lower, resulting in substantial savings for businesses that rely on shipping and logistics. Moreover, the longevity and durability of these sheets contribute to lower replacement and maintenance costs, offering a high return on investment over time. In medical applications, flexible plastic sheets are indispensable. They range from the production of sterile packaging solutions to the creation of medical-grade components such as tubing and blood bags. The ability to maintain sterilization standards while providing versatile solutions makes flexible plastic sheets a cornerstone of modern healthcare advancements. As experts continue to innovate and explore the potential of flexible plastic sheets, industries are witnessing enhanced product performance, reduced overheads, and improved environmental impact. The progression in material science has facilitated the development of sheets with greater strength, longevity, and application scope. As more businesses and industries adopt these materials, the market continues to evolve, driving demand for skilled professionals who can leverage their expertise to push the boundaries of what's possible with flexible plastic sheets. In summary, the role of flexible plastic sheets in various industries cannot be overstated. Their unique properties, coupled with advancements in sustainability and cost efficiency, position these sheets as not only a practical choice but also an environmentally responsible one. By integrating flexible plastic sheets into different applications, industries are not only optimizing their operations but also paving the way for innovative solutions that address current and future challenges. As such, professionals and industries alike should harness the potential of flexible plastic sheets to foster growth, sustainability, and increased competitiveness in their respective fields.

One cannot overlook the economic benefits of incorporating flexible plastic sheets into operations. Due to their lightweight nature, transportation costs are significantly lower, resulting in substantial savings for businesses that rely on shipping and logistics. Moreover, the longevity and durability of these sheets contribute to lower replacement and maintenance costs, offering a high return on investment over time. In medical applications, flexible plastic sheets are indispensable. They range from the production of sterile packaging solutions to the creation of medical-grade components such as tubing and blood bags. The ability to maintain sterilization standards while providing versatile solutions makes flexible plastic sheets a cornerstone of modern healthcare advancements. As experts continue to innovate and explore the potential of flexible plastic sheets, industries are witnessing enhanced product performance, reduced overheads, and improved environmental impact. The progression in material science has facilitated the development of sheets with greater strength, longevity, and application scope. As more businesses and industries adopt these materials, the market continues to evolve, driving demand for skilled professionals who can leverage their expertise to push the boundaries of what's possible with flexible plastic sheets. In summary, the role of flexible plastic sheets in various industries cannot be overstated. Their unique properties, coupled with advancements in sustainability and cost efficiency, position these sheets as not only a practical choice but also an environmentally responsible one. By integrating flexible plastic sheets into different applications, industries are not only optimizing their operations but also paving the way for innovative solutions that address current and future challenges. As such, professionals and industries alike should harness the potential of flexible plastic sheets to foster growth, sustainability, and increased competitiveness in their respective fields.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025