2 月 . 15, 2025 00:59

Back to list

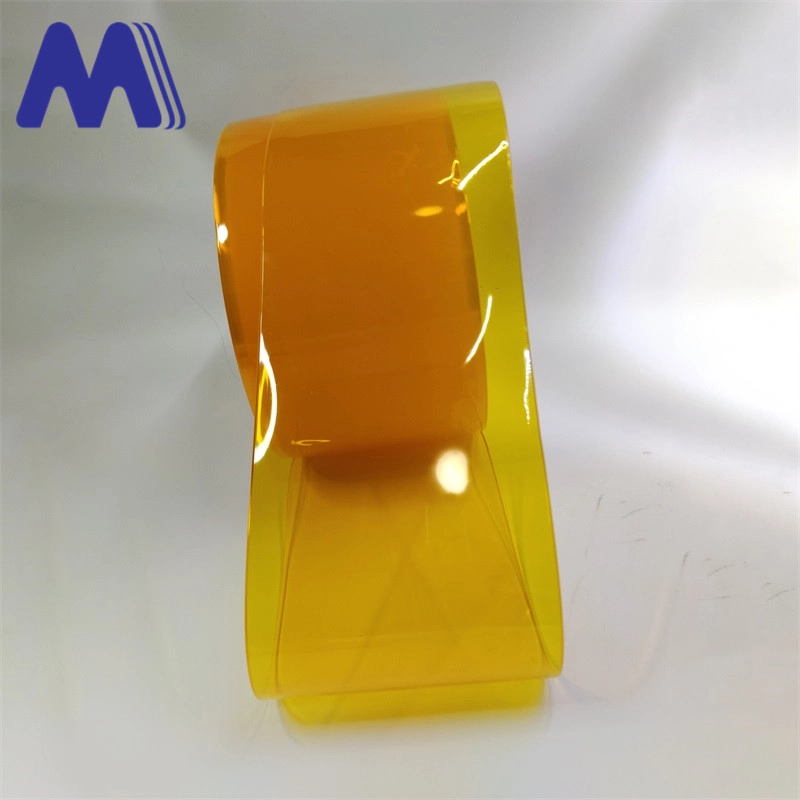

flexible plastic sheet

Flexible plastic sheets have revolutionized a plethora of industries due to their versatility and adaptability, making them an integral component of modern manufacturing and packaging processes. As an industry expert with years of experience, I can confidently assert the unmatched advantages these materials offer to businesses.

In recent years, sustainability has become a focal point of industrial development, and flexible plastic sheets have not been left behind. Addressing environmental concerns, manufacturers have been incorporating recycled materials into their production processes. Advancements in biodegradability and recyclability are also being pursued to minimize environmental impact, aligning the industry with global sustainability goals. Flexible plastic sheets have proven indispensable in sectors ranging from automotive to healthcare, where they serve as protective barriers, linings, or flexible components. Their ease of fabrication translates to cost savings on large projects, making them economically advantageous. Industry reports and case studies demonstrate the cost-effectiveness and efficiency brought about by flexible plastic sheet usage. For example, a construction company reduced project turnaround time significantly by switching to flexible plastic vapor barriers, resulting in substantial cost savings and enhanced client satisfaction. As the world continues to innovate, the role of flexible plastic sheets will undoubtedly expand. End-users, ranging from engineers to product developers, are advised to stay abreast of material advancements to leverage the broad capabilities of these versatile sheets fully. In conclusion, the adoption and integration of flexible plastic sheets across multiple industries not only highlight their versatility but also their capacity to meet modern-day industrial challenges. Their development is a testament to continuous innovation aimed at improving performance and sustainability, making these materials a critical asset to industries worldwide.

In recent years, sustainability has become a focal point of industrial development, and flexible plastic sheets have not been left behind. Addressing environmental concerns, manufacturers have been incorporating recycled materials into their production processes. Advancements in biodegradability and recyclability are also being pursued to minimize environmental impact, aligning the industry with global sustainability goals. Flexible plastic sheets have proven indispensable in sectors ranging from automotive to healthcare, where they serve as protective barriers, linings, or flexible components. Their ease of fabrication translates to cost savings on large projects, making them economically advantageous. Industry reports and case studies demonstrate the cost-effectiveness and efficiency brought about by flexible plastic sheet usage. For example, a construction company reduced project turnaround time significantly by switching to flexible plastic vapor barriers, resulting in substantial cost savings and enhanced client satisfaction. As the world continues to innovate, the role of flexible plastic sheets will undoubtedly expand. End-users, ranging from engineers to product developers, are advised to stay abreast of material advancements to leverage the broad capabilities of these versatile sheets fully. In conclusion, the adoption and integration of flexible plastic sheets across multiple industries not only highlight their versatility but also their capacity to meet modern-day industrial challenges. Their development is a testament to continuous innovation aimed at improving performance and sustainability, making these materials a critical asset to industries worldwide.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025