2 月 . 16, 2025 04:42

Back to list

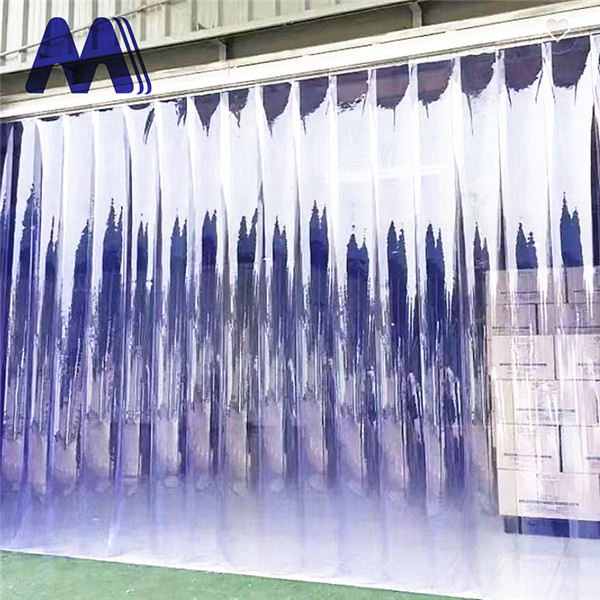

door pvc strip curtain

PVC strip curtains are an often understated yet profoundly effective solution for managing environments within numerous industries. Their significance extends beyond the simple task of partitioning spaces; they offer compelling advantages in terms of energy efficiency, hygiene control, and operational flexibility.

The practical application of PVC strip curtains extends into diverse environments. In food processing plants, they act as a barrier to contaminants, ensuring hygiene standards are maintained without impeding workflow. In warehouses, they help segregate work areas, optimizing the indoor climate by retaining heat or coolness and thus enhancing comfort for workers. Furthermore, the adoption of PVC strip curtains contributes to noise reduction. Their dense material effectively dampens sound transmission, creating a quieter and more productive workplace. This feature is particularly advantageous in industrial settings where machinery noise can be a significant concern. In terms of customization, businesses can select PVC strip curtains tailored to their specific needs. Options range from standard clear curtains to those that offer increased opacity for privacy or colored variants that align with branding efforts. This flexibility in design ensures that PVC strip curtains can seamlessly integrate into various operational environments without compromising aesthetic or functional requirements. In conclusion, PVC strip curtains represent a sophisticated solution amongst modern industrial products, providing unparalleled benefits across multiple metrics of business efficiency. Their proven track record in enhancing energy efficiency, combined with their regulatory compliance and adaptability, underscores their place as an indispensable resource in contemporary operational environments. As industries continue to evolve, the role of PVC strip curtains will undoubtedly expand, driven by ongoing innovations and a deepening understanding of their broader applicability.

The practical application of PVC strip curtains extends into diverse environments. In food processing plants, they act as a barrier to contaminants, ensuring hygiene standards are maintained without impeding workflow. In warehouses, they help segregate work areas, optimizing the indoor climate by retaining heat or coolness and thus enhancing comfort for workers. Furthermore, the adoption of PVC strip curtains contributes to noise reduction. Their dense material effectively dampens sound transmission, creating a quieter and more productive workplace. This feature is particularly advantageous in industrial settings where machinery noise can be a significant concern. In terms of customization, businesses can select PVC strip curtains tailored to their specific needs. Options range from standard clear curtains to those that offer increased opacity for privacy or colored variants that align with branding efforts. This flexibility in design ensures that PVC strip curtains can seamlessly integrate into various operational environments without compromising aesthetic or functional requirements. In conclusion, PVC strip curtains represent a sophisticated solution amongst modern industrial products, providing unparalleled benefits across multiple metrics of business efficiency. Their proven track record in enhancing energy efficiency, combined with their regulatory compliance and adaptability, underscores their place as an indispensable resource in contemporary operational environments. As industries continue to evolve, the role of PVC strip curtains will undoubtedly expand, driven by ongoing innovations and a deepening understanding of their broader applicability.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025