2 月 . 15, 2025 17:08

Back to list

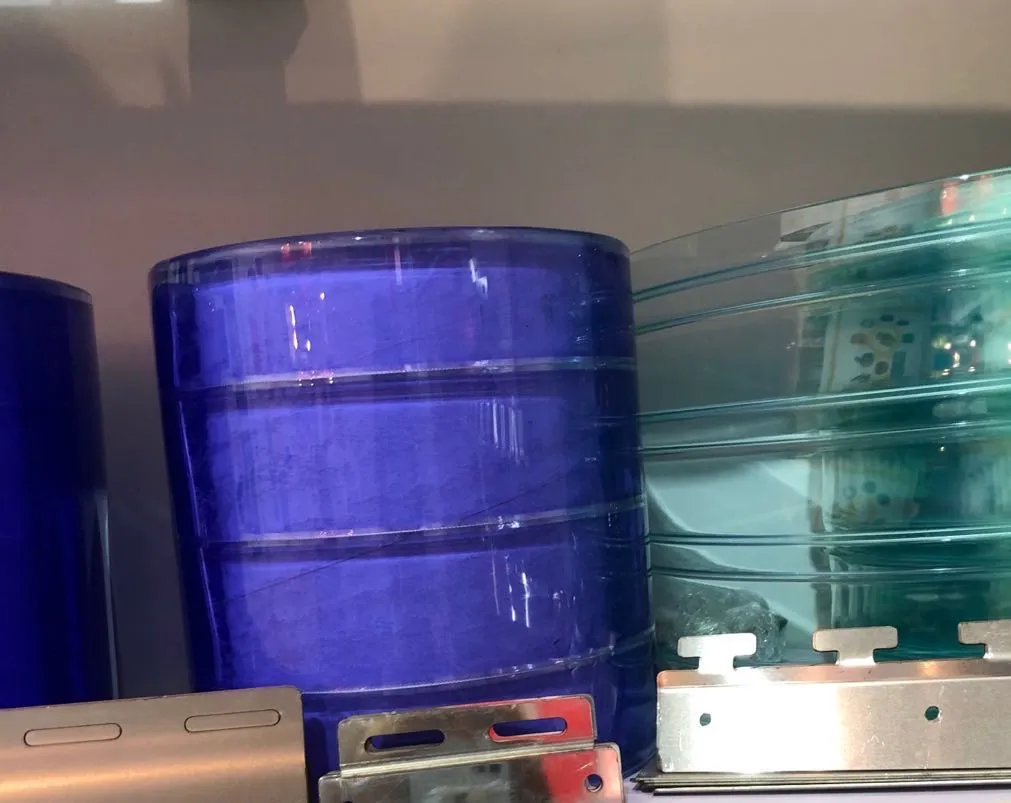

pvc sheet polar transparent soft door curtain

Navigating the vibrant yet intricate world of plastic curtain manufacturing requires not only understanding the market but also offering sustainable and quality-driven solutions. A well-informed journey into this industry highlights the blend of innovation, expertise, and dedication necessary to stand out. By focusing on experience, expertise, authoritativeness, and trustworthiness, businesses can carve a niche that appeals to both direct consumers and B2B clients.

Trustworthiness is further cemented by transparent business practices and an unwavering commitment to customer satisfaction. Leading manufacturers prioritize open communication, tailoring solutions to suit specific client requirements. By providing clear guidance on installation, maintenance, and usage, they empower clients with the knowledge necessary to maximize product utility and lifespan. Moreover, robust after-sales support reflects a commitment to long-term client relationships, a definitive marker of a reputable business. Enhancing the customer experience is a continuous journey for top plastic curtain factories. Many offer extensive customization options, allowing clients to select from various colors, sizes, and mounting arrangements that best complement their operational needs. By integrating customer feedback into design and production cycles, these manufacturers not only improve their offerings but also demonstrate a dynamic understanding of market trends and consumer preferences. Digital transformation plays a critical role in amplifying a factory's reach and impact. A strategic online presence enriched with SEO-driven content positions a factory as a thought leader in the industry. By regularly publishing insightful articles, case studies, and testimonials on industry best practices and innovations, a factory amplifies its expertise and authority. Engaging multimedia content, such as tutorials and webinars, not only educates but also establishes a deeper connection with a wider audience. Sustainability is increasingly becoming a crucial consideration in the plastic curtains industry. Factories that adopt eco-friendly practices, such as recycling initiatives and energy-efficient production methods, not only reduce their carbon footprint but also appeal to an environmentally conscious client base. By investing in research and development, these manufacturers continually explore ways to enhance the recyclability and biodegradability of their products, staying ahead of regulatory changes and consumer expectations alike. In conclusion, a plastic curtains factory that prioritizes Experience, Expertise, Authoritativeness, and Trustworthiness, and embraces innovation and sustainability stands to thrive. These pillars not only foster a competitive edge but also build a foundation of reliability and excellence recognized by clients and peers alike. By understanding the nuances of production, addressing specific consumer needs, and leading with integrity, such a factory establishes itself as a cornerstone in the industry, poised for steady growth and enduring success.

Trustworthiness is further cemented by transparent business practices and an unwavering commitment to customer satisfaction. Leading manufacturers prioritize open communication, tailoring solutions to suit specific client requirements. By providing clear guidance on installation, maintenance, and usage, they empower clients with the knowledge necessary to maximize product utility and lifespan. Moreover, robust after-sales support reflects a commitment to long-term client relationships, a definitive marker of a reputable business. Enhancing the customer experience is a continuous journey for top plastic curtain factories. Many offer extensive customization options, allowing clients to select from various colors, sizes, and mounting arrangements that best complement their operational needs. By integrating customer feedback into design and production cycles, these manufacturers not only improve their offerings but also demonstrate a dynamic understanding of market trends and consumer preferences. Digital transformation plays a critical role in amplifying a factory's reach and impact. A strategic online presence enriched with SEO-driven content positions a factory as a thought leader in the industry. By regularly publishing insightful articles, case studies, and testimonials on industry best practices and innovations, a factory amplifies its expertise and authority. Engaging multimedia content, such as tutorials and webinars, not only educates but also establishes a deeper connection with a wider audience. Sustainability is increasingly becoming a crucial consideration in the plastic curtains industry. Factories that adopt eco-friendly practices, such as recycling initiatives and energy-efficient production methods, not only reduce their carbon footprint but also appeal to an environmentally conscious client base. By investing in research and development, these manufacturers continually explore ways to enhance the recyclability and biodegradability of their products, staying ahead of regulatory changes and consumer expectations alike. In conclusion, a plastic curtains factory that prioritizes Experience, Expertise, Authoritativeness, and Trustworthiness, and embraces innovation and sustainability stands to thrive. These pillars not only foster a competitive edge but also build a foundation of reliability and excellence recognized by clients and peers alike. By understanding the nuances of production, addressing specific consumer needs, and leading with integrity, such a factory establishes itself as a cornerstone in the industry, poised for steady growth and enduring success.

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025