2 月 . 11, 2025 16:16

Back to list

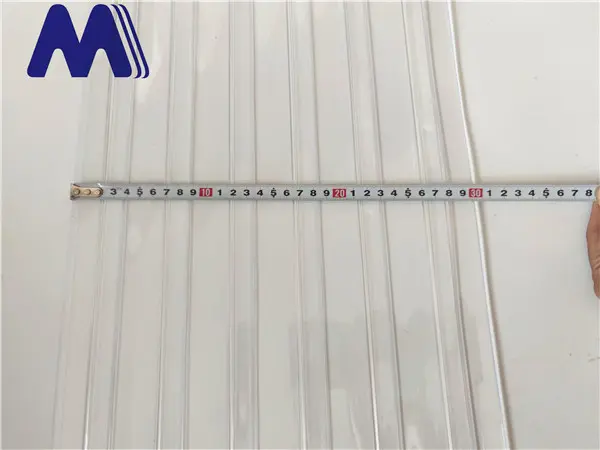

curtain pvc

PVC curtains, renowned for their versatility and durability, have emerged as a critical solution across various industrial and commercial sectors. These curtains serve as an efficient barrier to control environmental factors such as temperature, humidity, dust, and noise in warehouses, factories, cold storages, and retail spaces. Understanding the intricacies of PVC curtains and their applications can significantly enhance operational efficiency and provide substantial cost savings.

An authoritative understanding of PVC curtains also involves knowledge about their installation and maintenance. Installing PVC curtains involves minimal hassle and requires basic equipment. They can be customized to fit any entrance size, hence providing a barrier without compromising space flexibility. Regular maintenance entails simple cleaning procedures, making them cost-effective in the long run compared to permanent structures. Trustworthiness in PVC curtains as a product is underscored by stringent manufacturing standards that guarantee their reliability and durability. Most PVC curtains are made from high-grade, industry-certified materials that withstand extensive wear and tear. Consumers can rely on established manufacturers for quality products that offer warranties and customer support, enhancing peace of mind and investment security. For businesses contemplating the incorporation of PVC curtains, it's crucial to evaluate the specific requirements of their operational environment. Aspects such as ease of movement, frequency of passage, and environmental conditions should inform the choice of PVC curtain style and thickness. Expert consultation can often provide bespoke solutions that align with business needs and environmental regulations. In conclusion, PVC curtains stand out as a versatile and economical solution in managing environmental control across diverse industries. Their impact on enhancing operational efficiency, energy conservation, and hygiene cannot be overstated. By selecting the appropriate type, installing correctly, and ensuring regular maintenance, businesses can leverage the full potential of PVC curtains, underscoring their authority and sustainability in the market.

An authoritative understanding of PVC curtains also involves knowledge about their installation and maintenance. Installing PVC curtains involves minimal hassle and requires basic equipment. They can be customized to fit any entrance size, hence providing a barrier without compromising space flexibility. Regular maintenance entails simple cleaning procedures, making them cost-effective in the long run compared to permanent structures. Trustworthiness in PVC curtains as a product is underscored by stringent manufacturing standards that guarantee their reliability and durability. Most PVC curtains are made from high-grade, industry-certified materials that withstand extensive wear and tear. Consumers can rely on established manufacturers for quality products that offer warranties and customer support, enhancing peace of mind and investment security. For businesses contemplating the incorporation of PVC curtains, it's crucial to evaluate the specific requirements of their operational environment. Aspects such as ease of movement, frequency of passage, and environmental conditions should inform the choice of PVC curtain style and thickness. Expert consultation can often provide bespoke solutions that align with business needs and environmental regulations. In conclusion, PVC curtains stand out as a versatile and economical solution in managing environmental control across diverse industries. Their impact on enhancing operational efficiency, energy conservation, and hygiene cannot be overstated. By selecting the appropriate type, installing correctly, and ensuring regular maintenance, businesses can leverage the full potential of PVC curtains, underscoring their authority and sustainability in the market.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025