2 月 . 14, 2025 04:57

Back to list

Curtain

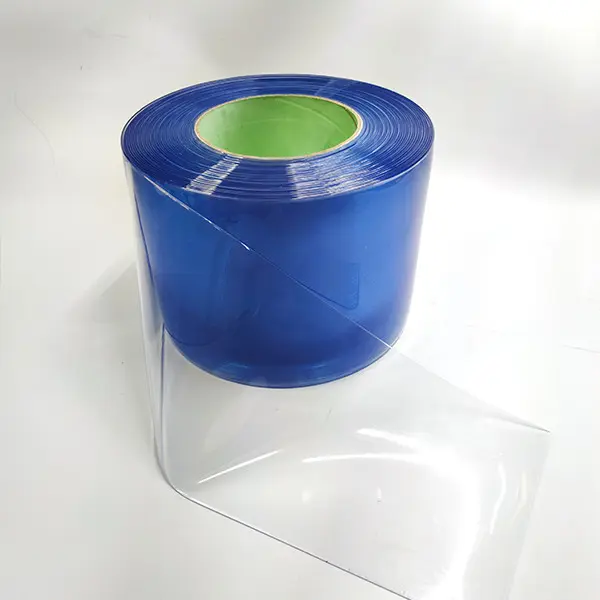

Enhancing efficiency and energy conservation in your coolroom environment demands innovative solutions, and coolroom PVC curtains stand at the forefront of optimizing performance and sustainability. These versatile installations blend expertise with practicality, becoming indispensable in industries ranging from food preservation to pharmaceutical storage.

Trustworthiness is fundamental when selecting partners for the installation of coolroom PVC curtains. Reputable providers offer comprehensive support, from initial consultation through to installation and maintenance. This service commitment ensures that clients receive not just a product, but a complete solution tailored to their operational challenges. Established companies often provide warranties and guarantees, a testament to their confidence in the quality and performance of their products. In practice, the benefits of coolroom PVC curtains have been experienced across various sectors. In the food industry, they play a vital role in minimizing cross-contamination risks, a crucial factor in preventing foodborne illnesses. Reports from major dairy producers, for example, highlight significant extensions in product shelf life and quality preservation through the use of these curtains. Similarly, pharmaceutical storage facilities report improved regulation of critical storage conditions, ensuring that sensitive medications remain effective and safe for consumer use. As industries continue to strive for operational efficiency and environmental responsibility, coolroom PVC curtains emerge as a sophisticated solution. Their role transcends beyond mere temperature regulation; they represent an integration of innovative design, professional expertise, and certified authority. Their trustworthiness is manifested through tangible outcomes such as cost savings, enhanced hygiene, and compliance with industry standards. Future advancements in coolroom PVC curtain technology promise even greater efficiency gains. Innovations in material technology and design are set to offer enhanced insulation properties, further reducing energy wastage. Additionally, automation and smart technology integration could allow these systems to adapt dynamically to environmental changes, optimizing performance in real time. Investing in coolroom PVC curtains is not simply a step towards improved temperature control; it is a decisive move towards sustainable and efficient operations. Industries looking to enhance their environmental footprint and operational costs would do well to consider this innovative solution, securing not only their present operational needs but the sustainability of their future as well.

Trustworthiness is fundamental when selecting partners for the installation of coolroom PVC curtains. Reputable providers offer comprehensive support, from initial consultation through to installation and maintenance. This service commitment ensures that clients receive not just a product, but a complete solution tailored to their operational challenges. Established companies often provide warranties and guarantees, a testament to their confidence in the quality and performance of their products. In practice, the benefits of coolroom PVC curtains have been experienced across various sectors. In the food industry, they play a vital role in minimizing cross-contamination risks, a crucial factor in preventing foodborne illnesses. Reports from major dairy producers, for example, highlight significant extensions in product shelf life and quality preservation through the use of these curtains. Similarly, pharmaceutical storage facilities report improved regulation of critical storage conditions, ensuring that sensitive medications remain effective and safe for consumer use. As industries continue to strive for operational efficiency and environmental responsibility, coolroom PVC curtains emerge as a sophisticated solution. Their role transcends beyond mere temperature regulation; they represent an integration of innovative design, professional expertise, and certified authority. Their trustworthiness is manifested through tangible outcomes such as cost savings, enhanced hygiene, and compliance with industry standards. Future advancements in coolroom PVC curtain technology promise even greater efficiency gains. Innovations in material technology and design are set to offer enhanced insulation properties, further reducing energy wastage. Additionally, automation and smart technology integration could allow these systems to adapt dynamically to environmental changes, optimizing performance in real time. Investing in coolroom PVC curtains is not simply a step towards improved temperature control; it is a decisive move towards sustainable and efficient operations. Industries looking to enhance their environmental footprint and operational costs would do well to consider this innovative solution, securing not only their present operational needs but the sustainability of their future as well.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025