2 月 . 10, 2025 09:33

Back to list

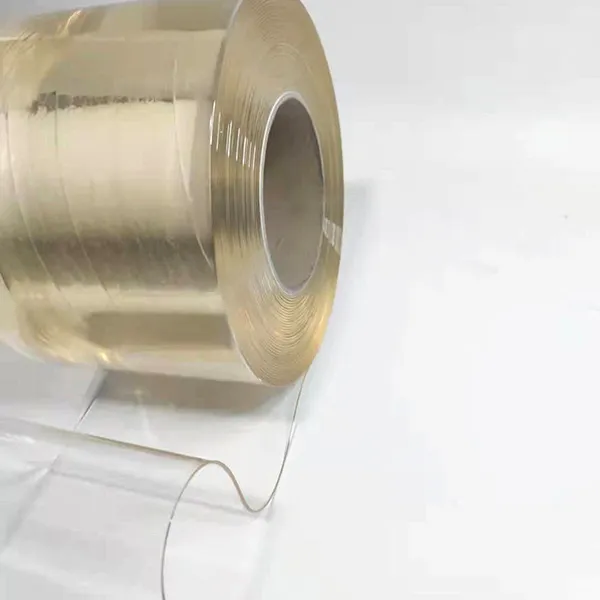

cold room curtains

Cold room curtains play a crucial role in maintaining the efficiency and functionality of cold storage facilities. These essential components serve as thermal barriers that help in controlling temperature, reducing energy costs, and minimizing contamination risks. In a demanding environment where efficiency and hygiene are paramount, the choice of cold room curtains can significantly impact operational success.

From a standpoint of authoritativeness, industry standards like the British Standard BS EN 12546-12000, which pertains to insulation for refrigerated vehicles and containers, highlight the importance of appropriate temperature control systems, including cold room curtains. Such standards assure that buyers are investing in technology that meets rigorous safety and efficiency benchmarks. Trustworthiness of suppliers can be assessed by verifying their compliance with these standards, examining their track record, and analyzing customer reviews. Reliable manufacturers provide documentation on the material’s source, its compliance, and test results that confirm its performance metrics. This transparency ensures that clients are making informed decisions backed by solid evidence and practical efficiency outcomes. Beyond functional benefits, cold room curtains also promote operational flexibility, allowing staff to move in and out of storage areas efficiently without compromising temperature controls. The convenience offered by these curtains enhances workflow in busy environments, reducing the downtime associated with traditional door mechanisms. In conclusion, the strategic implementation of cold room curtains is a smart move for any business reliant on cold storage. These curtains not only enhance the efficiency of cooling systems but also contribute positively to environmental sustainability by reducing energy consumption. Critical for companies across various sectors—from pharmaceuticals to agriculture—investing in high-quality cold room curtains underscores a commitment to operational excellence and product quality. With correct installation and maintenance, these curtains are not merely an accessory but an integral part of a sophisticated temperature management system.

From a standpoint of authoritativeness, industry standards like the British Standard BS EN 12546-12000, which pertains to insulation for refrigerated vehicles and containers, highlight the importance of appropriate temperature control systems, including cold room curtains. Such standards assure that buyers are investing in technology that meets rigorous safety and efficiency benchmarks. Trustworthiness of suppliers can be assessed by verifying their compliance with these standards, examining their track record, and analyzing customer reviews. Reliable manufacturers provide documentation on the material’s source, its compliance, and test results that confirm its performance metrics. This transparency ensures that clients are making informed decisions backed by solid evidence and practical efficiency outcomes. Beyond functional benefits, cold room curtains also promote operational flexibility, allowing staff to move in and out of storage areas efficiently without compromising temperature controls. The convenience offered by these curtains enhances workflow in busy environments, reducing the downtime associated with traditional door mechanisms. In conclusion, the strategic implementation of cold room curtains is a smart move for any business reliant on cold storage. These curtains not only enhance the efficiency of cooling systems but also contribute positively to environmental sustainability by reducing energy consumption. Critical for companies across various sectors—from pharmaceuticals to agriculture—investing in high-quality cold room curtains underscores a commitment to operational excellence and product quality. With correct installation and maintenance, these curtains are not merely an accessory but an integral part of a sophisticated temperature management system.

Prev:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025