3 月 . 06, 2025 14:14

Back to list

Curtain

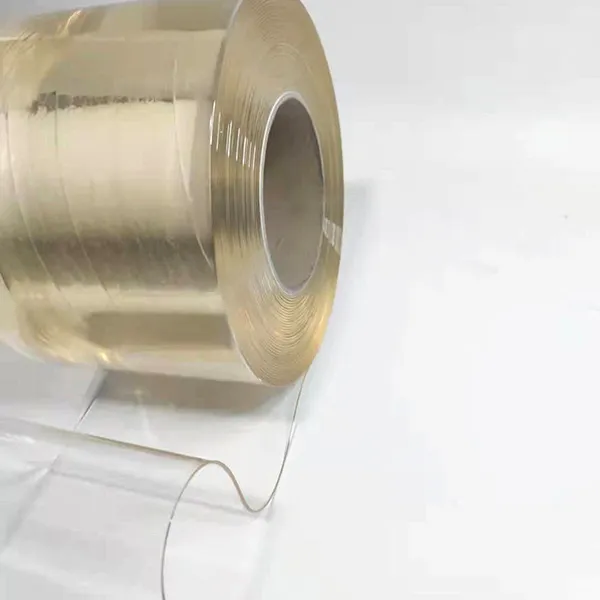

Anti-static PVC curtains, a marvel of modern engineering, offer an essential solution to numerous industries plagued by static electricity issues. These transparent, flexible curtains are engineered specifically to mitigate the accumulation of static electricity, a common nemesis in sectors ranging from electronics manufacturing to pharmaceuticals. The technology behind anti-static PVC curtains combines years of innovation with a keen understanding of electrostatic discharge (ESD) control principles.

Beyond their functional benefits, anti-static PVC curtains are also celebrated for their versatility and ease of installation. Available in various sizes and configurations, they can be customized to meet specific environmental requirements, ensuring optimal performance in any setting. Their transparent nature allows for unobstructed visibility, facilitating smooth operations without compromising safety measures. Maintenance of these curtains is straightforward, requiring only regular cleaning with antistatic solutions to sustain their effectiveness. This low-maintenance aspect, combined with their durable design, ensures a cost-effective solution for long-term static control. Furthermore, they contribute to energy efficiency by acting as thermal barriers, mitigating the loss of conditioned air and reducing utility costs. Industries that have integrated anti-static PVC curtains into their processes report a marked improvement in product quality and employee safety. The curtains mitigate the risk of electrostatic discharge, which can lead to product defects or, in severe cases, personnel injury. This proactive approach to static management not only preserves the integrity of sensitive components but also fosters a safe working environment conducive to productivity and innovation. In conclusion, anti-static PVC curtains provide an indispensable tool for modern industries grappling with static electricity challenges. Their scientific design, compliance with industry standards, and proven application history elevate them as a trusted solution in static control. As industries continue to evolve, the demand for such advanced solutions is only expected to grow, further solidifying the role of anti-static PVC curtains in achieving operational excellence and safeguarding quality and safety.

Beyond their functional benefits, anti-static PVC curtains are also celebrated for their versatility and ease of installation. Available in various sizes and configurations, they can be customized to meet specific environmental requirements, ensuring optimal performance in any setting. Their transparent nature allows for unobstructed visibility, facilitating smooth operations without compromising safety measures. Maintenance of these curtains is straightforward, requiring only regular cleaning with antistatic solutions to sustain their effectiveness. This low-maintenance aspect, combined with their durable design, ensures a cost-effective solution for long-term static control. Furthermore, they contribute to energy efficiency by acting as thermal barriers, mitigating the loss of conditioned air and reducing utility costs. Industries that have integrated anti-static PVC curtains into their processes report a marked improvement in product quality and employee safety. The curtains mitigate the risk of electrostatic discharge, which can lead to product defects or, in severe cases, personnel injury. This proactive approach to static management not only preserves the integrity of sensitive components but also fosters a safe working environment conducive to productivity and innovation. In conclusion, anti-static PVC curtains provide an indispensable tool for modern industries grappling with static electricity challenges. Their scientific design, compliance with industry standards, and proven application history elevate them as a trusted solution in static control. As industries continue to evolve, the demand for such advanced solutions is only expected to grow, further solidifying the role of anti-static PVC curtains in achieving operational excellence and safeguarding quality and safety.

Prev:

Next:

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025