1 月 . 25, 2025 05:36

Back to list

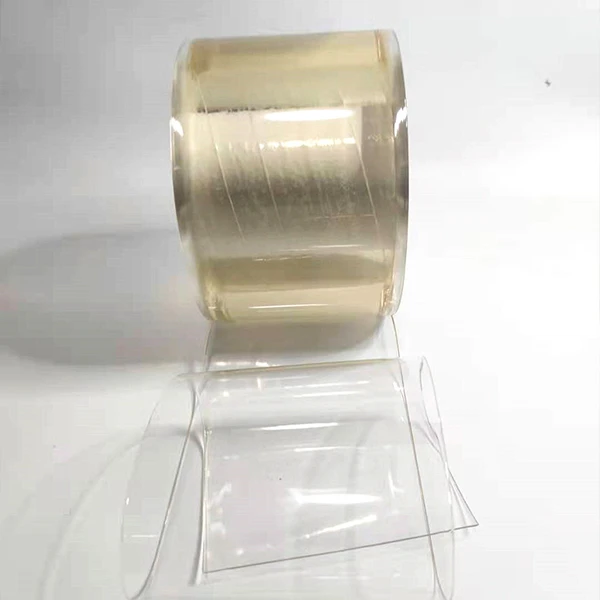

PVC Transparent blue Clear Smooth Plastic PVC Strip Door Curtains cold curtain

The industrial world constantly seeks solutions that enhance productivity, safety, and efficiency in workspaces. One such innovation, the anti-static PVC curtain, is rapidly gaining recognition, particularly in sectors reliant on stringent electrostatic discharge (ESD) control measures. These curtains are not only practical but are engineered with a level of expertise and authority that makes them indispensable in safeguarding sensitive environments.

Trustworthiness is further established through certifications and robust quality assurance processes. Reputable manufacturers subject their anti-static curtains to stringent testing, ensuring they meet or exceed industry standards such as ANSI/ESD S20.20 or IEC 61340. When businesses choose these certified solutions, they are assured of enhanced ESD control and adherence to global safety protocols, fostering a sense of trust and reliability. Moreover, the installation of anti-static PVC curtains is straightforward, adaptable to various industrial setups. Their modular design means they can be customized to fit any configuration, offering flexibility and ease of maintenance. This practical application benefits businesses seeking cost-effective, efficient solutions to static control without necessitating extensive alterations to existing infrastructure. From an environmental standpoint, the adoption of anti-static PVC curtains also aligns with sustainability goals. Leading manufacturers are increasingly focused on reducing the environmental impact of their products, incorporating recyclable materials and non-toxic compounds in their curtains. This shift towards eco-friendly production not only fulfills a critical social responsibility but also appeals to environmentally-conscious businesses looking to mitigate their ecological footprint. Innovation and expertise have combined to make anti-static PVC curtains a cornerstone of modern industrial safety measures. Their presence in critical workspaces mitigates ESD risks, enhances product integrity, and aligns with the technological advancements demanded by contemporary industries. As more companies recognize the importance of electrostatic discharge control, the authority and reliability of anti-static PVC curtains will undoubtedly establish them as essential components in the quest for safer, more efficient industrial environments.

Trustworthiness is further established through certifications and robust quality assurance processes. Reputable manufacturers subject their anti-static curtains to stringent testing, ensuring they meet or exceed industry standards such as ANSI/ESD S20.20 or IEC 61340. When businesses choose these certified solutions, they are assured of enhanced ESD control and adherence to global safety protocols, fostering a sense of trust and reliability. Moreover, the installation of anti-static PVC curtains is straightforward, adaptable to various industrial setups. Their modular design means they can be customized to fit any configuration, offering flexibility and ease of maintenance. This practical application benefits businesses seeking cost-effective, efficient solutions to static control without necessitating extensive alterations to existing infrastructure. From an environmental standpoint, the adoption of anti-static PVC curtains also aligns with sustainability goals. Leading manufacturers are increasingly focused on reducing the environmental impact of their products, incorporating recyclable materials and non-toxic compounds in their curtains. This shift towards eco-friendly production not only fulfills a critical social responsibility but also appeals to environmentally-conscious businesses looking to mitigate their ecological footprint. Innovation and expertise have combined to make anti-static PVC curtains a cornerstone of modern industrial safety measures. Their presence in critical workspaces mitigates ESD risks, enhances product integrity, and aligns with the technological advancements demanded by contemporary industries. As more companies recognize the importance of electrostatic discharge control, the authority and reliability of anti-static PVC curtains will undoubtedly establish them as essential components in the quest for safer, more efficient industrial environments.

Latest news

-

Flexible PVC Sheet Supplier – Durable Flexible Plastic & Ribbed Sheets Custom SolutionsNewsJun.10,2025

-

Magnetic Curtain Wide – Durable, Easy Install, Perfect Fit for DoorsNewsJun.10,2025

-

Flat Anti-Insect PVC Strip Curtain Effective Insect Control SolutionNewsJun.10,2025

-

Opaque PVC Strip Curtains Insect-Proof & Privacy SolutionsNewsMay.30,2025

-

3mm PVC Sheets - Durable, Lightweight & Waterproof 1mm & Rolls AvailableNewsMay.30,2025

-

Polar Curtains Energy-Efficient Thermal Insulation Solutions Shop NowNewsMay.29,2025